Got any suggestions?

We want to hear from you! Send us a message and help improve Slidesgo

Top searches

Trending searches

115 templates

178 templates

student council

50 templates

99 templates

734 templates

hispanic heritage month

22 templates

Kaizen, Quality Management Method

It seems that you like this template, kaizen, quality management method presentation, free google slides theme, powerpoint template, and canva presentation template.

The Kaizen method is a philosophy of continuous improvement that has gained popularity in the business world. The concept is simple yet powerful: small, incremental changes lead to significant progress over time. Slidesgo wasn't built in one day—it's been a journey of small steps until we got to the top! We have prepared this template, with some Japanese inspiration, to make it easy for you to explain the Kaizen method and, possibly, propose it in your own business. It includes a calligraphic font for the titles and completely editable slides.

Features of this template

- 100% editable and easy to modify

- 35 different slides to impress your audience

- Contains easy-to-edit graphics such as graphs, maps, tables, timelines and mockups

- Includes 500+ icons and Flaticon’s extension for customizing your slides

- Designed to be used in Google Slides, Canva, and Microsoft PowerPoint

- 16:9 widescreen format suitable for all types of screens

- Includes information about fonts, colors, and credits of the resources used

How can I use the template?

Am I free to use the templates?

How to attribute?

Attribution required If you are a free user, you must attribute Slidesgo by keeping the slide where the credits appear. How to attribute?

Register for free and start downloading now

Related posts on our blog.

How to Add, Duplicate, Move, Delete or Hide Slides in Google Slides

How to Change Layouts in PowerPoint

How to Change the Slide Size in Google Slides

Related presentations.

Premium template

Unlock this template and gain unlimited access

Newly Launched - AI Presentation Maker

AI PPT Maker

Design Services

Business PPTs

Business Plan

Introduction PPT

Self Introduction

Startup Business Plan

Cyber Security

Digital Marketing

Project Management

Product Management

Artificial Intelligence

Target Market

Communication

Supply Chain

Google Slides

Research Services

All Categories

Kaizen PowerPoint Presentation Templates and Google Slides

Save your time and attract your audience with our fully editable ppt templates and slides..

DISPLAYING: 60 of 230 Items

- You're currently reading page 1

Kaizen Pdca Cycle Process Ppt PowerPoint Presentation Complete Deck With Slides

This is a kaizen pdca cycle process ppt powerpoint presentation complete deck with slides. This is a one stage process. The stages in this process are business, marketing, planning, strategy, finance.

Kaizen Planning Implementing And Controlling Ppt PowerPoint Presentation Complete Deck With Slides

This is a kaizen planning implementing and controlling ppt powerpoint presentation complete deck with slides. This is a one stage process. The stages in this process are business, marketing, planning, strategy, controlling.

Kaizen Action Plan Data Collection And Analysis Techniques Ppt PowerPoint Presentation Complete Deck With Slides

This is a kaizen action plan data collection and analysis techniques ppt powerpoint presentation complete deck with slides. This is a one stage process. The stages in this process are action plan, kaizen, data management, analysis, technology.

Kaizen Process Ppt PowerPoint Presentation Complete Deck With Slides

Boost your confidence and team morale with this well-structured Kaizen Process Ppt PowerPoint Presentation Complete Deck With Slides. This prefabricated set gives a voice to your presentation because of its well-researched content and graphics. Our experts have added all the components very carefully, thus helping you deliver great presentations with a single click. Not only that, it contains a set of thirty four slides that are designed using the right visuals, graphics, etc. Various topics can be discussed, and effective brainstorming sessions can be conducted using the wide variety of slides added in this complete deck. Apart from this, our PPT design contains clear instructions to help you restructure your presentations and create multiple variations. The color, format, design anything can be modified as deemed fit by the user. Not only this, it is available for immediate download. So, grab it now.

Kaizen Methodology Ppt PowerPoint Presentation Complete Deck With Slides

If designing a presentation takes a lot of your time and resources and you are looking for a better alternative, then this kaizen methodology ppt powerpoint presentation complete deck with slides is the right fit for you. This is a prefabricated set that can help you deliver a great presentation on the topic. All the thirteen slides included in this sample template can be used to present a birds-eye view of the topic. These slides are also fully editable, giving you enough freedom to add specific details to make this layout more suited to your business setting. Apart from the content, all other elements like color, design, theme are also replaceable and editable. This helps in designing a variety of presentations with a single layout. Not only this, you can use this PPT design in formats like PDF, PNG, and JPG once downloaded. Therefore, without any further ado, download and utilize this sample presentation as per your liking.

Kaizen Plan Do Check Act Model Ppt PowerPoint Presentation Complete Deck With Slides

Boost your confidence and team morale with this well-structured Kaizen Plan Do Check Act Model Ppt PowerPoint Presentation Complete Deck With Slides. This prefabricated set gives a voice to your presentation because of its well-researched content and graphics. Our experts have added all the components very carefully, thus helping you deliver great presentations with a single click. Not only that, it contains a set of twelve slides that are designed using the right visuals, graphics, etc. Various topics can be discussed, and effective brainstorming sessions can be conducted using the wide variety of slides added in this complete deck. Apart from this, our PPT design contains clear instructions to help you restructure your presentations and create multiple variations. The color, format, design anything can be modified as deemed fit by the user. Not only this, it is available for immediate download. So, grab it now.

Kaizen Implementation Steps Planning Continuous Ppt PowerPoint Presentation Complete Deck

This kaizen implementation steps planning continuous ppt powerpoint presentation complete deck acts as backup support for your ideas, vision, thoughts, etc. Use it to present a thorough understanding of the topic. This PPT slideshow can be utilized for both in-house and outside presentations depending upon your needs and business demands. Entailing twelve slides with a consistent design and theme, this template will make a solid use case. As it is intuitively designed, it suits every business vertical and industry. All you have to do is make a few tweaks in the content or any other component to design unique presentations. The biggest advantage of this complete deck is that it can be personalized multiple times once downloaded. The color, design, shapes, and other elements are free to modify to add personal touches. You can also insert your logo design in this PPT layout. Therefore a well-thought and crafted presentation can be delivered with ease and precision by downloading this kaizen implementation steps planning continuous ppt powerpoint presentation complete deck PPT slideshow.

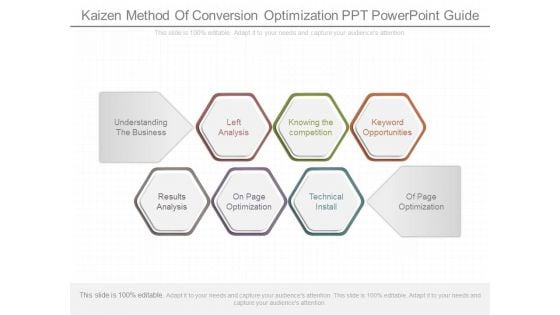

Kaizen Method Of Conversion Optimization Ppt Powerpoint Guide

This is a kaizen method of conversion optimization ppt powerpoint guide. This is a six stage process. The stages in this process are understanding the business, left analysis, knowing the competition, keyword opportunities, results analysis, on page optimization, technical install, of page optimization.

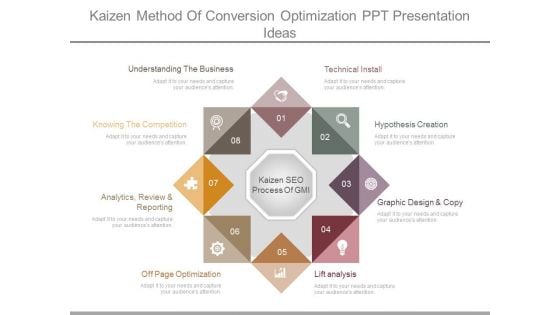

Kaizen Method Of Conversion Optimization Ppt Presentation Ideas

This is a kaizen method of conversion optimization ppt presentation ideas. This is a eight stage process. The stages in this process are understanding the business, technical install, hypothesis creation, graphic design and copy, lift analysis, off page optimization, analytics review and reporting, knowing the competition, kaizen seo process of gmi.

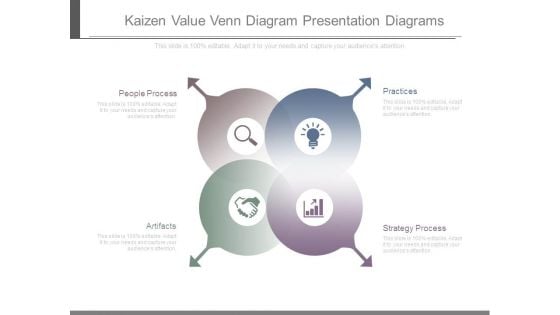

Kaizen Value Venn Diagram Presentation Diagrams

This is a kaizen value venn diagram presentation diagrams. This is a four stage process. The stages in this process are people process, artifacts, practices, strategy process.

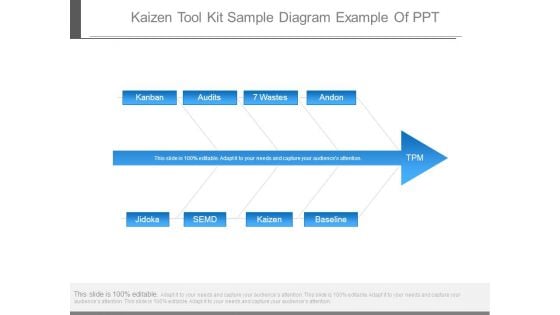

Kaizen Tool Kit Sample Diagram Example Of Ppt

This is a kaizen tool kit sample diagram example of ppt. This is a four stage process. The stages in this process are kanban, audits, wastes, andon, jidoka, semd, kaizen, baseline.

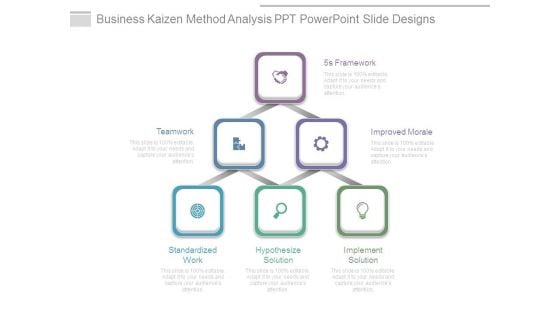

Business Kaizen Method Analysis Ppt Powerpoint Slide Designs

This is a business kaizen method analysis ppt powerpoint slide designs. This is a six stage process. The stages in this process are teamwork, standardized work, hypothesize solution, implement solution, improved morale, 5s framework.

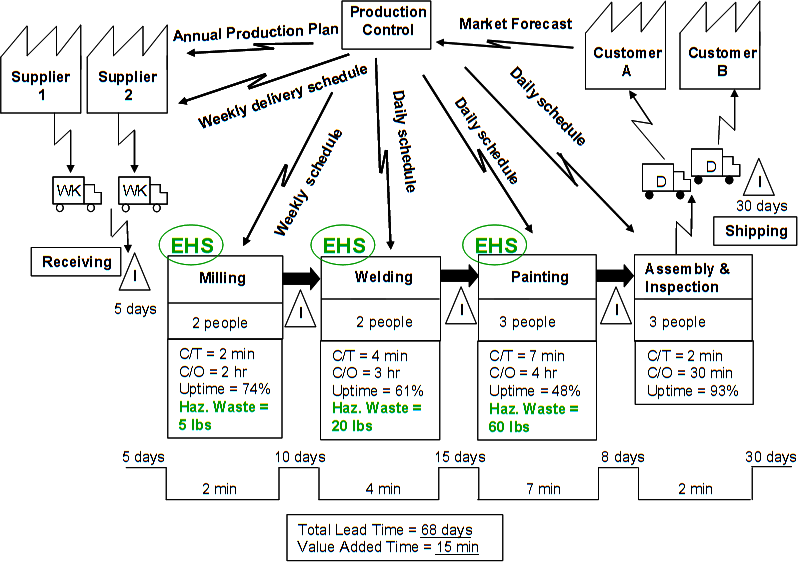

Value Stream Mapping With Kaizen Ppt America Powerpoint Themes

This is a value stream mapping with kaizen ppt america powerpoint themes. This is a five stage process. The stages in this process are sacramento, wyoming, cheyenne, pennsylvania, harrisburg, california, texas, austin, tallahassee, florida.

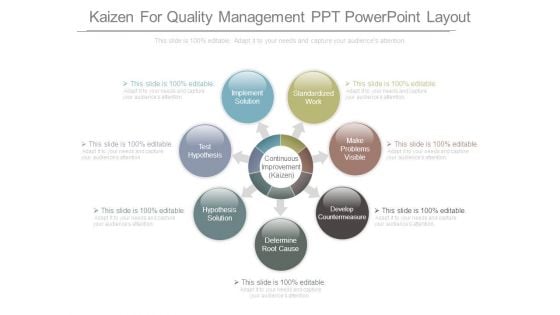

Kaizen For Quality Management Ppt Powerpoint Layout

This is a kaizen for quality management ppt powerpoint layout. This is a seven stage process. The stages in this process are continuous improvement kaizen, standardized work, make problems visible, develop countermeasure, determine root cause, hypothesis solution, test hypothesis, implement solution.

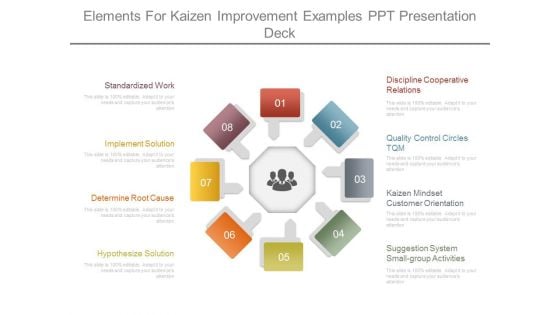

Elements For Kaizen Improvement Examples Ppt Presentation Deck

This is a elements for kaizen improvement examples ppt presentation deck. This is a eight stage process. The stages in this process are standardized work, implement solution, determine root cause, hypothesize solution, discipline cooperative relations, quality control circles tqm, kaizen mindset customer orientation, suggestion system small-group activities.

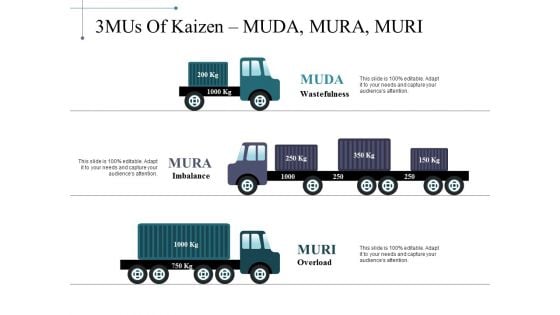

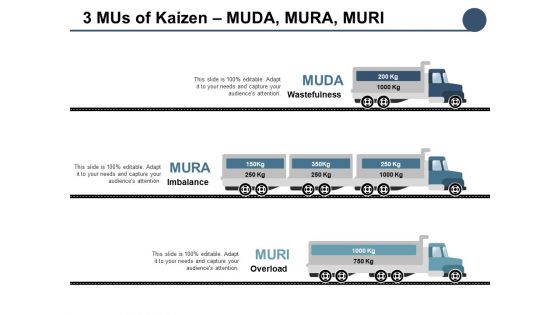

3Mus Of Kaizen Muda Mura Muri Ppt PowerPoint Presentation Layouts Gridlines

This is a 3mus of kaizen muda mura muri ppt powerpoint presentation layouts gridlines. This is a three stage process. The stages in this process are muda, wastefulness, mura, imbalance, muri, overload.

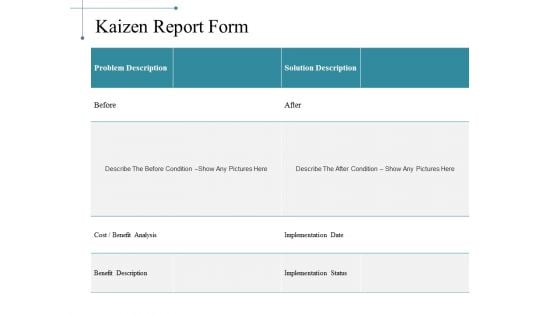

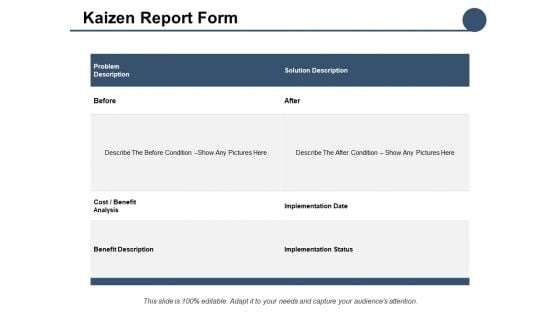

Kaizen Report Form Ppt PowerPoint Presentation Styles Samples

This is a kaizen report form ppt powerpoint presentation styles samples. This is a four stage process. The stages in this process are problem description, solution description, before, after, implementation date.

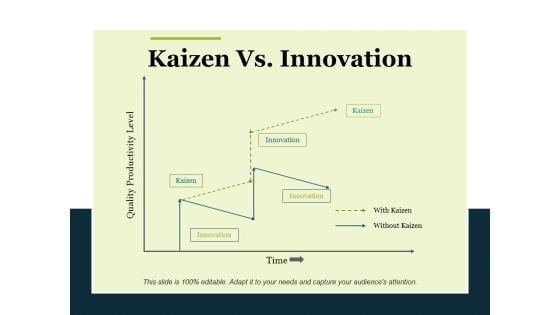

Kaizen Vs Innovation Ppt PowerPoint Presentation Slides Download

This is a kaizen vs innovation ppt powerpoint presentation slides download. This is a four stage process. The stages in this process are kaizen, innovation, time, quality productivity level, without kaizen.

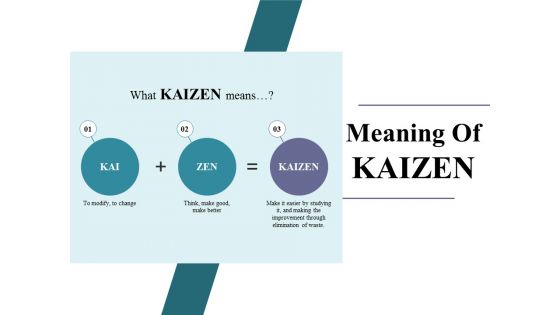

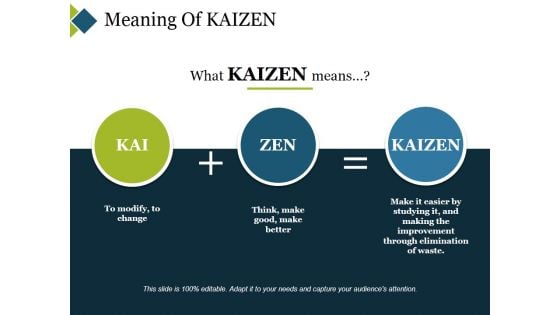

Meaning Of Kaizen Ppt PowerPoint Presentation Ideas Portfolio

This is a meaning of kaizen ppt powerpoint presentation ideas portfolio. This is a three stage process. The stages in this process are to modify, to change, think, make good, make better, make it easier by studying it, and making the improvement through elimination of waste.

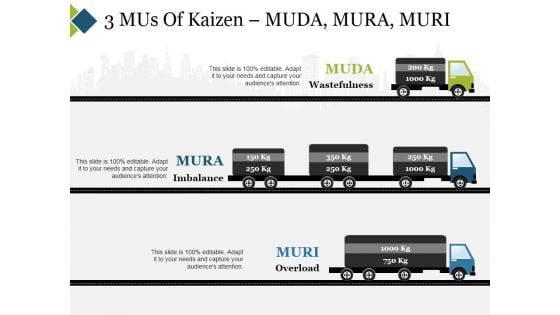

3 Mus Of Kaizen Muda Mura Muri Ppt PowerPoint Presentation Professional Introduction

This is a 3 mus of kaizen muda mura muri ppt powerpoint presentation professional introduction. This is a three stage process. The stages in this process are wastefulness, imbalance, overload, business, marketing.

Kaizen Report Form Ppt PowerPoint Presentation Gallery Rules

This is a kaizen report form ppt powerpoint presentation gallery rules. This is a two stage process. The stages in this process are problem description, solution description, before, after, benefit analysis.

Kaizen Vs Innovation Ppt PowerPoint Presentation Model Graphic Images

This is a kaizen vs innovation ppt powerpoint presentation model graphic images. This is a five stage process. The stages in this process are quality productivity level, kaizen, innovation, time, business.

Meaning Of Kaizen Ppt PowerPoint Presentation Slides Layout

This is a meaning of kaizen ppt powerpoint presentation slides layout. This is a three stage process. The stages in this process are business, marketing, kai, zen, kaizen.

High Impact Kaizen Event Corporate Improvement Fulfilment Logistics Ppt PowerPoint Presentation Professional Designs

This is a high impact kaizen event corporate improvement fulfilment logistics ppt powerpoint presentation professional designs. This is a three stage process. The stages in this process are high impact kaizen event corporate improvement, fulfilment logistics.

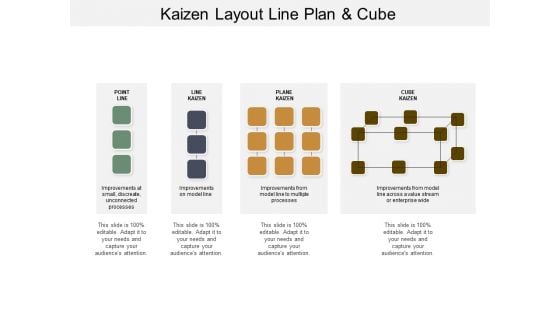

Kaizen Layout Line Plan And Cube Ppt PowerPoint Presentation Inspiration Images

This is a kaizen layout line plan and cube ppt powerpoint presentation inspiration images. This is a four stage process. The stages in this process are diagram of kaizen, diagram of improvements, diagram of enhancement.

Kaizen Model To Sustain Improvements Ppt PowerPoint Presentation Gallery Professional

This is a kaizen model to sustain improvements ppt powerpoint presentation gallery professional. This is a four stage process. The stages in this process are diagram of kaizen, diagram of improvements, diagram of enhancement.

Kaizen Improvement Process Problem Action Result Ppt PowerPoint Presentation Portfolio Example File

This is a kaizen improvement process problem action result ppt powerpoint presentation portfolio example file. This is a two stage process. The stages in this process are before vs after, comparison, compare.

Kaizen 5S Lean Methodology Ppt PowerPoint Presentation Styles Summary Cpb

This is a kaizen 5s lean methodology ppt powerpoint presentation styles summary cpb. This is a five stage process. The stages in this process are kaizen 5s lean methodology.

Human Resource Training Development Lean Manufacturing Kaizen Brainstorm Ppt PowerPoint Presentation Icon Graphics

This is a human resource training development lean manufacturing kaizen brainstorm ppt powerpoint presentation icon graphics. This is a four stage process. The stages in this process are human resource training development, lean manufacturing kaizen, brainstorm.

Business Plan Kaizen Rapid Improvement Process Lean Management Ppt PowerPoint Presentation Ideas Elements

This is a business plan kaizen rapid improvement process lean management ppt powerpoint presentation ideas elements. This is a two stage process. The stages in this process are business plan, kaizen rapid improvement process, lean management.

Products Marketing Advantages Production Planning 5S Kaizen Management Ppt PowerPoint Presentation Styles Infographic Template

This is a products marketing advantages production planning 5s kaizen management ppt powerpoint presentation styles infographic template. This is a stage process. The stages in this process are products marketing, advantages production planning, 5s kaizen management.

5S Kaizen Principles Cost Accounting Ppt PowerPoint Presentation Show Objects

This is a 5s kaizen principles cost accounting ppt powerpoint presentation show objects. This is a six stage process. The stages in this process are 5s, kaizen, principles, cost, accounting.

System Analysis Design Kaizen Innovation Ppt PowerPoint Presentation Infographics Summary

This is a system analysis design kaizen innovation ppt powerpoint presentation infographics summary. This is a three stage process. The stages in this process are system analysis design, kaizen innovation.

Employment Opportunities Kaizen Event Ppt PowerPoint Presentation Model Skills

This is a employment opportunities kaizen event ppt powerpoint presentation model skills. This is a five stage process. The stages in this process are employment opportunities, kaizen event.

Kaizen Events Manufacturing Risk Preparedness Sales Management Assessment Ppt PowerPoint Presentation Gallery Pictures

This is a kaizen events manufacturing risk preparedness sales management assessment ppt powerpoint presentation gallery pictures. This is a three stage process. The stages in this process are kaizen events manufacturing, risk preparedness, sales management assessment.

3 Mus Of Kaizen Muda Mura Muri Ppt PowerPoint Presentation Outline Layout

This is a 3 mus of kaizen muda mura muri ppt powerpoint presentation outline layout. This is a three stage process. The stages in this process are business, management, planning, strategy, marketing.

Kaizen 5S Framework Good Housekeeping Ppt PowerPoint Presentation Icon Outline

This is a kaizen 5s framework good housekeeping ppt powerpoint presentation icon outline. This is a four stage process. The stages in this process are business, management, planning, strategy, marketing.

Kaizen Before And After Template Ppt PowerPoint Presentation Icon Objects

This is a kaizen before and after template ppt powerpoint presentation icon objects. This is a three stage process. The stages in this process are business, management, planning, strategy, marketing.

Kaizen Report Form Ppt PowerPoint Presentation Summary Professional

This is a kaizen report form ppt powerpoint presentation summary professional. This is a two stage process. The stages in this process are business, management, planning, strategy, marketing.

Kaizen Vs Innovation Ppt PowerPoint Presentation Infographics Example File

This is a kaizen vs innovation ppt powerpoint presentation infographics example file. This is a five stage process. The stages in this process are business, management, planning, strategy, marketing.

Meaning Of Kaizen Ppt PowerPoint Presentation Gallery Graphic Tips

This is a meaning of kaizen ppt powerpoint presentation gallery graphic tips. This is a three stage process. The stages in this process are business, management, planning, strategy, marketing.

Thank You Example Kaizen Presenation Ppt PowerPoint Presentation Inspiration Structure

This is a thank you example kaizen presenation ppt powerpoint presentation inspiration structure. This is a one stage process. The stages in this process are thank you.

Kaizen Leader Ppt PowerPoint Presentation Icon Images Cpb

This is a kaizen leader ppt powerpoint presentation icon images cpb. This is a five stage process. The stages in this process are kaizen leader.

10 Principles Kaizen Ppt PowerPoint Presentation Slides Designs Cpb

This is a 10 principles kaizen ppt powerpoint presentation slides designs cpb. This is a three stage process. The stages in this process are 10 principles kaizen.

5S Kaizen Services Ppt PowerPoint Presentation File Example Topics Cpb

This is a 5s kaizen services ppt powerpoint presentation file example topics cpb. This is a six stage process. The stages in this process are 5s kaizen services.

Kaizen Event Characteristic Ppt PowerPoint Presentation Gallery Themes Cpb

This is a kaizen event characteristic ppt powerpoint presentation gallery themes cpb. This is a six stage process. The stages in this process are kaizen event characteristic.

Check List Kaizen Steps Ppt Powerpoint Presentation Pictures Guide Cpb

This is a check list kaizen steps ppt powerpoint presentation pictures guide cpb. This is a five stage process. The stages in this process are check list kaizen steps.

Kaizen Engagement Model Ppt Powerpoint Presentation Background Cpb

This is a kaizen engagement model ppt powerpoint presentation background cpb. This is a three stage process. The stages in this process are kaizen engagement model.

Kaizen Event Characteristic Ppt Powerpoint Presentation Gallery Slides Cpb

This is a kaizen event characteristic ppt powerpoint presentation gallery slides cpb. This is a four stage process. The stages in this process are kaizen event characteristic.

Kaizen Events Process Ppt Powerpoint Presentation Icon Slide Portrait Cpb

This is a kaizen events process ppt powerpoint presentation icon slide portrait cpb. This is a three stage process. The stages in this process are kaizen events process.

Kaizen Leader Role Ppt Powerpoint Presentation File Show Cpb

This is a kaizen leader role ppt powerpoint presentation file show cpb. This is a three stage process. The stages in this process are kaizen leader role.

Kaizen Leadership Management Ppt Powerpoint Presentation Inspiration Icons Cpb

This is a kaizen leadership management ppt powerpoint presentation inspiration icons cpb. This is a five stage process. The stages in this process are kaizen leadership management.

Kaizen Process Ppt Powerpoint Presentation Professional Inspiration Cpb

This is a kaizen process ppt powerpoint presentation professional inspiration cpb. This is a four stage process. The stages in this process are kaizen process.

Kaizen Quality Improvement Ppt Powerpoint Presentation Background Designs Cpb

This is a kaizen quality improvement ppt powerpoint presentation background designs cpb. This is a five stage process. The stages in this process are kaizen quality improvement.

Lean Kaizen 9 Step Ppt Powerpoint Presentation Portfolio Rules Cpb

This is a lean kaizen 9 step ppt powerpoint presentation portfolio rules cpb. This is a five stage process. The stages in this process are lean kaizen 9 step.

Kaizen Services Business Ppt PowerPoint Presentation Summary Master Slide Cpb

This is a kaizen services business ppt powerpoint presentation summary master slide cpb. This is a five stage process. The stages in this process are kaizen services business.

Kaizen Visual Management Process Ppt PowerPoint Presentation Icon Templates Cpb

This is a kaizen visual management process ppt powerpoint presentation icon templates cpb. This is a four stage process. The stages in this process are kaizen visual management process.

Kaizen 5S Standard Work Ppt PowerPoint Presentation Icon Gallery Cpb

This is a kaizen 5s standard work ppt powerpoint presentation icon gallery cpb. This is a four stage process. The stages in this process are kaizen 5s standard work.

Kaizen Production Method Ppt Ppt PowerPoint Presentation Pictures Cpb

This is a kaizen production method ppt ppt powerpoint presentation pictures cpb. This is a three stage process. The stages in this process are kaizen production method ppt.

Kaizen Process Improvement Cycle With Icons Ppt PowerPoint Presentation Outline Slideshow

Presenting this set of slides with name kaizen process improvement cycle with icons ppt powerpoint presentation outline slideshow. This is a four stage process. The stages in this process are pdca cycle, process improvement, continuous process. This is a completely editable PowerPoint presentation and is available for immediate download. Download now and impress your audience.

Ratings and Reviews

Most relevant reviews, by ajay mohan.

June 10, 2021

by Vladimir

By tumpa singha ray.

June 11, 2021

by Ankita Jhamb

June 12, 2021

Items 1 to 10 of 95 total

- What is Strategy?

- Business Models

- Developing a Strategy

- Strategic Planning

- Competitive Advantage

- Growth Strategy

- Market Strategy

- Customer Strategy

- Geographic Strategy

- Product Strategy

- Service Strategy

- Pricing Strategy

- Distribution Strategy

- Sales Strategy

- Marketing Strategy

- Digital Marketing Strategy

- Organizational Strategy

- HR Strategy – Organizational Design

- HR Strategy – Employee Journey & Culture

- Process Strategy

- Procurement Strategy

- Cost and Capital Strategy

- Business Value

- Market Analysis

- Problem Solving Skills

- Strategic Options

- Business Analytics

- Strategic Decision Making

- Process Improvement

- Project Planning

- Team Leadership

- Personal Development

- Leadership Maturity Model

- Leadership Team Strategy

- The Leadership Team

- Leadership Mindset

- Communication & Collaboration

- Problem Solving

- Decision Making

- People Leadership

- Strategic Execution

- Executive Coaching

- Strategy Coaching

- Business Transformation

- Strategy Workshops

- Leadership Strategy Survey

- Leadership Training

- Who’s Joe?

“Without continual growth and progress, such words as improvement, achievement, and success have no meaning.”

– Benjamin Franklin

During the 1980s, facing stiff and unrelenting competition from Japanese manufacturers, American manufacturers tried to leverage lean methodologies and tools to transform their productivity and quality. Unfortunately, many of their efforts failed miserably. They would bring in consultants or tiger teams to lean out processes only to see people revert back to wasteful methods. They were missing the heart and engine of lean, which is kaizen.

What is Kaizen?

Kaizen is the philosophy that every person in an organization , from the CEO to the janitor, has a DUTY to improve what they do, eliminate waste on a daily basis, continually learn, reflect, change and experiment . And, the overall efficiency and effectiveness of an organization are predicated on the emergence and compounded impact of thousands of small improvements and changes driven by every individual in an organization. While western thinking typically seeks out big step-function innovations, eastern thinking focuses on the sum of the parts of many little improvements. It is hard for western management teams to comprehend the fact that over the past 50 years there have been over 1,000,000 systemic improvements to the Toyota production system.

In Japanese, kai means “change” and zen means “good”, which translated into English means “continuous improvement.” While Toyota pioneered many of the core lean improvement tools, they also perfected kaizen, which embodies the cultural and philosophical underpinnings of lean.

Kaizen methodology – PDCA

Kaizen expands beyond the idea of the individual pursuing continuous improvement; there is also the methodology of kaizen, which at its most basic level is applying the scientific method to processes. The prerequisite of kaizen is that you have standardized processes, with the thought being if a process is in flux and changing, then you can’t truly understand cause and effect in a controlled way. So, first, standardize your processes and get them up to level 4 in the process maturity levels.

Once you have standardized processes, then the first step in kaizen is to observe and identify waste. Once you identify waste, then the next step is a reflection to truly understand the waste and diagnose the root cause of it. The third step is the beginning of the Deming Cycle, which is a simple process improvement framework of Plan, Do, Check, and Act (PDCA). Plan involves designing an improvement to a process. Do is implementing the plan. Check involves measuring the impact of the plan on the efficiency and effectiveness of the process. And, Act, is deciding what permanent changes will be adopted and standardized in the process.

In Toyota’s thinking, there are two types of kaizen (improvement). The first is what we refer to as Kaizen with a capital K. This is the big win. In the west, this is what companies typically seek. In Toyota, people prefer kaizen with a small k, which are the small day-to-day efforts that improve a process. In the east, Plan, Do, Study, Act is a daily ritual.

Kaizen can happen informally as part of someone’s daily job or through a simple suggestion box. Or, kaizen can happen more formally through a planned and intense kaizen workshop, where a team comes together for a few days to problem-solve a process. A kaizen workshop involves understanding the needs of the customer, mapping out the current state of a process, identifying waste in the process and root causes of the waste, mapping out a future state of the process, and building an implementation plan to pilot changes, evaluate their impact, and ultimately make permanent changes to standardize within the process.

Why is kaizen important?

It is hard to believe the amount of waste in most processes until you go through a Kaizen exercise on a process and see the waste firsthand. Whether or not you adopt the formal methodologies of kaizen, the underpinning philosophy of kaizen can be useful. The philosophy of continuous improvement and that everyone should be proactive in identifying waste, creating solutions, implementing positive change, learning, and experimenting is essential to continuously improve organizational performance . The era of command and control management is extinct, and survival is predicated on nurturing and encouraging the empowerment and duty of every individual to drive positive continuous change.

How do you embrace kaizen?

There is no easy answer to how to embrace kaizen within an organization. It took Toyota many decades to perfect the kaizen cultural norms of continuous reflection, idea generation, controlled experimentation , standardization, and sharing. Kaizen is not about the tools but instead is about the deep seeded culture of an organization. Whereas Toyota team members look at waste and issues as an opportunity for the team and organization to improve, westerners often look at waste and issues as somebody’s problem, mistake, and a reason to potentially fire them. Western thinking is often about breakthrough innovation and step function improvements, while Toyota has implemented over 1 million small and large improvements to its production processes through Kaizen. Western thinking often obsesses on getting the results; while kaizen thinking is that the right process will produce the right results. There aren’t any quick tips or tricks to embracing kaizen since it is a long road that requires considerable commitment, dedication, resources, and thoughtfulness.

NEXT SECTION: SIX SIGMA & DMAIC

DOWNLOAD STRATEGY PRESENTATION TEMPLATES

THE $150 VALUE PACK - 600 SLIDES 168-PAGE COMPENDIUM OF STRATEGY FRAMEWORKS & TEMPLATES 186-PAGE HR & ORG STRATEGY PRESENTATION 100-PAGE SALES PLAN PRESENTATION 121-PAGE STRATEGIC PLAN & COMPANY OVERVIEW PRESENTATION 114-PAGE MARKET & COMPETITIVE ANALYSIS PRESENTATION 18-PAGE BUSINESS MODEL TEMPLATE

JOE NEWSUM COACHING

EXECUTIVE COACHING STRATEGY COACHING ELEVATE360 BUSINESS TRANSFORMATION STRATEGY WORKSHOPS LEADERSHIP STRATEGY SURVEY & WORKSHOP STRATEGY & LEADERSHIP TRAINING

THE LEADERSHIP MATURITY MODEL

Explore other types of strategy.

BIG PICTURE WHAT IS STRATEGY? BUSINESS MODEL COMP. ADVANTAGE GROWTH

TARGETS MARKET CUSTOMER GEOGRAPHIC

VALUE PROPOSITION PRODUCT SERVICE PRICING

GO TO MARKET DISTRIBUTION SALES MARKETING

ORGANIZATIONAL ORG DESIGN HR & CULTURE PROCESS PARTNER

EXPLORE THE TOP 100 STRATEGIC LEADERSHIP COMPETENCIES

TYPES OF VALUE MARKET ANALYSIS PROBLEM SOLVING

OPTION CREATION ANALYTICS DECISION MAKING PROCESS TOOLS

PLANNING & PROJECTS PEOPLE LEADERSHIP PERSONAL DEVELOPMENT

Home PowerPoint Templates Kaizen

Kaizen PowerPoint Templates

Download pre-designed Kaizen PPT templates and slide designs for presentations. Kaizen is a system of continuous improvement in quality, technology, processes, company culture, productivity, safety and leadership. Download awesome Kaizen slide designs and PPT templates that you can use in presentations on total quality management and continuous improvement slide designs.

Kaizen PICK Chart Template for PowerPoint

Kaizen Muda Mura Muri Template for PowerPoint

Quality Tradeoff Curve for PowerPoint

5S Diagram Template for PowerPoint

Download unlimited content, our annual unlimited plan let you download unlimited content from slidemodel. save hours of manual work and use awesome slide designs in your next presentation..

Continuous Improvement Kaizen

What do you think of this template.

Product details

Some companies, achieving success, continue to develop it. Others, after their meteoric rise, will face the same rapid decline. What helps these companies consistently be the first? Continuous improvement Kaizen is an approach to understand the business reality that targeting and achieving smaller but continuous goals can result in a bigger and positive change. Either for the company or the market, the concept of Kaizen applies to both. Completely editable and customizable, this continuous improvement kaizen template comprises of 4 slides. This template is designed in a modern style and uses stylish infographics. If necessary, you can independently change the font sizes and color of the infographics so that this template will organically fit into your presentations. It remains in use for Commercial purposes; presentations and proposals in Industrial Sectors, National and Multi-National companies, Health Sectors and Technology Development areas. It is also used for Academic purposes in research or thesis development procedures.

The first slide consists of six rectangular boxes, represented in contrasting combination of colors and each linked to a common region of focus, the concept of Pure Improvement. This slide will primarily be useful to all production workers. It was in Toyota production that this system of continuous improvement arose. For example, a shop or team leader can make changes to their production processes based on their observations and work practices. They can share this technique through this slide, formulating key messages for other teams in the plant. Product managers can use this slide when preparing a methodology for testing a new product. For example, you can describe the processes that need to be performed on a product and repeat the steps with minor process adjustments. The second slide is more of a hexagonal representation of the same concept with description boxes alongside. This slide gives you the opportunity to outline the key messages for the next milestones – know your customer, the core of Kaizen, be transparent, let it flow, go to Gemba, empower people. You can also use it when describing the actions that are required to achieve the company’s goal. The next slide differs from the previous one in a richer color scheme and a more stylish icon design. You can use this slide to optimize processes in your company. For example, you can use this slide to describe the processes for delivering products that reduce delivery costs and shorten delivery times. For example, you describe your suppliers and your interactions with them, and how you can reduce storage costs by unloading a large vehicle directly into small vans for delivery around town. The fourth slide is a bit different. It contains four rectangular boxes namely Plan, Do, Act and Study. However, the core concept remains the same. To gather a list of problems, get your employees involved, encourage solution ideas, test, analyze results, adopt the successful proposal and repeat. This slide can be used by business coaches in their personal growth programs. Also, this slide can be used by team leaders in their weekly meetings with programmers. You can prepare a description of the processes that are repeated with each development of the software product and discuss with team members how to improve the processes at each stage. This template will be a worthy addition to your collection of presentation templates.

Related Products

RACI Matrix Template

Exit Strategy

Eisenhower Matrix Template

Recruitment Strategy

30-60-90 Day Project Plan

Failure Mode & Effects Analysis

Diagram of Bridges

Progress Tracker

SIPOC Template

Iceberg Concept Diagram

You dont have access, please change your membership plan., great you're all signed up..., verify your account.

PowerSlides.com will email you template files that you've chosen to dowload.

Please make sure you've provided a valid email address! Sometimes, our emails can end up in your Promotions/Spam folder.

Simply, verify your account by clicking on the link in your email.

Filter by Keywords

Project Management

10 kaizen examples for continuous improvement.

June 15, 2024

Start using ClickUp today

- Manage all your work in one place

- Collaborate with your team

- Use ClickUp for FREE—forever

Post World War II, Japan needed a miraculous overhaul to recover from the devastation caused to the public’s morale, infrastructure, and industries. The Kaizen philosophy came in as their savior; it went beyond fixing what was broken and pushed them toward striving to be better.

This philosophy became the cornerstone of Japan’s economic miracle, an iterative process propelling the nation from devastation to a global economic powerhouse.

Kai means ‘making a change,’ and zen means a way or a path.’ Today, this philosophy translates to ‘continuous improvement’.

This philosophy was turned into a strategy in lean manufacturing, wherein employees at all levels actively collaborate to make ongoing, small-scale process improvements in manufacturing, unleashing the company’s collective potential for constant betterment.

In this blog post, we’ll cover how Kaizen as a philosophy has evolved, review Kaizen examples, and explore tools for implementing this philosophy.

Core principles of Kaizen

Setting the tone: management commitment, the role of empowerment in kaizen, root cause analysis: critical problem solving in kaizen , the seven types of muda [waste] and how kaizen mitigates them, using value stream mapping in kaizen , designing a process improvement strategy with kaizen , the importance of change management in kaizen, 1. step-by-step guide to successful kaizen implementation , 2. preparing for a kaizen event, 3. the role of leadership in a successful implementation, 4. kaizen implementation: key success factors, benefits and impact of utilizing kaizen, kaizen tools and resources, implement the kaizen business philosophy with clickup to grow your business.

Understanding the Kaizen Methodology

Kaizen methodology emerged in post-WWII Japan as a way of rebuilding the nation’s economy and, with it, its spirit.

American statistician W. Edward Deming arrived in Japan in the early 1950s to share statistical control processes to aid recovery. However, at Toyota, he found workers already using a scientific approach. Deming adapted his concepts into the Plan-Do-Check-Act [PDCA] cycle , which was followed by the workers during that time and has evolved ever since

Taiichi Ohno, a Toyota manager and Deming’s contemporary, incorporated Deming’s ideas, his own experience on the shop floor studying time and motion, and even elements of Henry Ford’s mass production [highly respected in Japan] into the manufacturing process.

Ohno’s guiding principle was ‘some days little up, some days big up’—the core of Kaizen’s incremental improvement philosophy. This fusion of various influences led to the creation of the Toyota Production System [TPS], which remains the gold standard for Kaizen and continuous improvement .

Since then, the spread of Japanese business philosophies has significantly impacted global business practices.

To understand the true meaning of Kaizen, let’s go through its core principles:

- Collaborative teamwork: Everyone contributes to a culture of continuous improvement

- Standardized practices: Discipline in following efficient processes is key

- Empowered employees: Problem-solving together boosts morale and engagement

- Quality circles: Regular meetings for identifying and solving work area issues ensure quality is consistent

- Open communication: A safe space for admitting mistakes and suggesting improvements helps people approach the team without hesitation

Kaizen is, therefore, part action plan and part philosophy.

As an action plan, it includes organized improvement events where cross-functional teams, especially plant floor employees, tackle specific areas. And as a philosophy, it creates a culture where all employees actively suggest and implement improvements, becoming involved in every aspect of a lean company.

Management commitment is when the higher level executives directly participate in an organization’s critical program or aspect.

In Kaizen, managers are responsible for implementation and are the main motivators during the process. They should empower and encourage all company members to participate in every supply chain process and commit to full performance in their roles.

Traditionally, factory work followed rigid hierarchies and strict product management rules with limited employee input. Kaizen flips this script!

Kaizen hinges on empowering employees at all levels. By encouraging suggestions and active participation with continuous improvement tools , employees feel valued and invested in the company’s success.

As a result, a sense of ownership is created, fueling creative problem-solving. Empowered workers are more likely to identify inefficiencies and propose solutions, leading to a more agile and adaptable organization that continuously strives for improvement.

The Process of Kaizen

Kaizen thrives on a constant loop of problem-solving and improvement. It all starts with recognizing an issue or an opportunity for a better way of doing things.

This acknowledgment triggers action:

- Identify the target: Define the specific problem or area for improvement

- Analyze current state: Deep dive into how things are currently done

- Develop the ideal solution: Brainstorm and identify the best possible solution

- Implement and test: Put the solution into action and evaluate its effectiveness

- Refine and standardize: Make adjustments based on results and establish the improved process as the new standard

- Repeat: With the problem addressed, identify the next area for improvement, restarting the continuous cycle of Kaizen

Root cause analysis [RCA] is a systematic method for identifying and fixing the underlying causes of a product or process’s defects, errors, or failures.

When implemented in RCA, Kaizen can help organizations identify the root causes of problems and continuously improve their processes to prevent them from reoccurring.

RCA is an important tool in continuous improvement methodologies such as Lean Manufacturing and Six Sigma. It involves investigating negative effect patterns, finding hidden system flaws, and discovering specific actions contributing to the problem.

One well-known RCA technique is the 5 Whys technique, which involves repeatedly asking ‘Why?’ in different ways at least five times to uncover the layers of symptoms.

Example : Late product shipments using Root Cause Analysis with Kaizen

Problem : A company is experiencing frequent delays in shipping finished products to customers.

Root Cause Analysis [RCA] with Kaizen :

The company assembles a cross-functional team with representatives from production, logistics, and sales. The team:

- Analyzes shipping records to identify the frequency and extent of delays

- Interviews production staff about the challenges they face

- Reviews communication logs between departments to identify any gaps

5 Whys Analysis : The team gathers around a visual representation of the process [e.g., flowchart] and asks “Why” questions about the delays:

- Why are shipments delayed? [Possible answer: Inventory shortages]

- Why are there inventory shortages? [Possible answer: Production bottlenecks]

- Why are there production bottlenecks? [Possible answer: Machine breakdowns]

- Why are machines breaking down? [Possible answer: Lack of preventative maintenance]

- Why is there a lack of preventative maintenance? [Possible answer: Inefficient maintenance scheduling]

Based on the analysis, the root cause could be the lack of preventative maintenance causing machine breakdowns and production delays.

Kaizen improvement suggestions :

- Implement a preventative maintenance schedule for machines to avoid breakdowns

- Train production staff on basic machine maintenance tasks

- Improve communication between departments to ensure timely inventory management

- The new preventative maintenance plan becomes the standard operating procedure. The team monitors shipping performance to ensure delays are minimized

The Kaizen cycle con

Lean manufacturing has been heavily influenced by the Toyota Production System, which prioritizes eliminating waste, or ‘Muda’ in Japanese, within the production process.

Here’s how the Kaizen method tackles each type of Muda:

- Overproduction: It refers to making more than needed, leading to storage costs, potential obsolescence, and unnecessary resource allocation. Here, Kaizen promotes just-in-time [JIT] manufacturing, producing only what’s required when it’s needed

- Inventory: Excessive stockpiling ties up capital, requires storage space, and risks product spoilage. Kaizen emphasizes lean inventory management through methods like Kanban systems, ensuring a smooth flow of materials only when needed for production

- Transportation: Moving materials or products unnecessarily wastes time and resources. Kaizen promotes minimizing transportation distances and streamlining production flow

- Overprocessing: Performing unnecessary steps or using overly complex procedures slows down production. Kaizen encourages process simplification and waste elimination, focusing on activities that add value to the final product

- Motion: Inefficient worker movements or poorly designed workstations hinder productivity. Kaizen promotes ergonomics and workstation optimization to minimize unnecessary movements and maximize worker efficiency

- Waiting: Idle time due to machine breakdowns, material shortages, or production delays represents lost productivity. Kaizen emphasizes preventive maintenance and improved communication to minimize equipment downtime and keep production flowing smoothly

- Defects: Producing faulty products leads to rework, scrap, and customer dissatisfaction. Kaizen promotes quality control practices and continuous improvement throughout the production process to minimize defects and ensure consistent quality output

When put into practice, Kaizen reduces costs, improves accuracy, and establishes efficiency in every step of lean manufacturing.

Effective Kaizen Techniques

Kaizen offers a toolbox of techniques for tackling waste, simplifying processes, and achieving lasting improvements across an organization’s various aspects.

The following techniques will help you understand how to merge Kaizen within your workflows to create an action plan for continuous improvement.

Kaizen principles emphasize continuous improvement, and value stream mapping is a powerful tool for enhancing process quality.

A Kaizen Value Stream Mapping [VSM] workshop is a multi-day event [2–5 days] where cross-functional teams collaborate to identify and eliminate waste. While doing a series of activities, the team creates maps depicting the current, ideal, and future state of their chosen product or service.

These activities include:

- Gemba walk: The team observes the process to gain a deep understanding of its current state

- Mapping the current state: A visual map is created, documenting every step in the process and differentiating the steps that add value in the eyes of the customer from those that do not [value analysis]. The time spent on each step is also calculated [flow analysis]

- Brainstorming improvements: The team identifies opportunities to eliminate inefficiencies [waste] and streamline the process, envisioning the ideal state

- Mapping the future state: A Value Strem Map that represents the optimized process with minimized waste is created

- Developing an action plan: Concrete steps to implement the improvements and achieve the future state are defined

Process improvement isn’t just for factory floors. While it often tackles manufacturing productivity, its power extends across your organization.

Here’s where you can identify bottlenecks, simplify workflows, and unlock hidden potential:

- Manufacturing: System downtime disrupts production. Process improvements get things started again

- Administration: Bogged down by endless approvals? Streamline the process and free up time

- Employee engagement: Disempowered workers with limited tasks? Empower them for better results

- Communication: Drowning in email and Slack? Improve communication channels and save time

- Inventory management: Excess inventory ties up resources. Optimize processes to avoid stockpiles

- Billing and time management: Excessive non-billable hours eat into profits. Identify time-wasters and improve efficiency

- Data redundancy: Duplicate reports waste time and effort. Consolidate processes for a single source of truth

Change management is important for the successful implementation of Kaizen. It’s the process of planning, implementing, and evaluating organizational changes . It involves communicating, engaging, and supporting stakeholders, especially employees who may be resistant to change.

True success with continuous improvement goes beyond a program. It’s about a cultural transformation where every employee takes ownership of improving things. Embedding continuous improvement into your company’s DNA drives lasting results, not a superficial implementation.

How to Implement Kaizen in Your Business

The Kaizen mindset can be cumbersome to implement and track, especially when you’re just starting to establish the process in your manufacturing business.

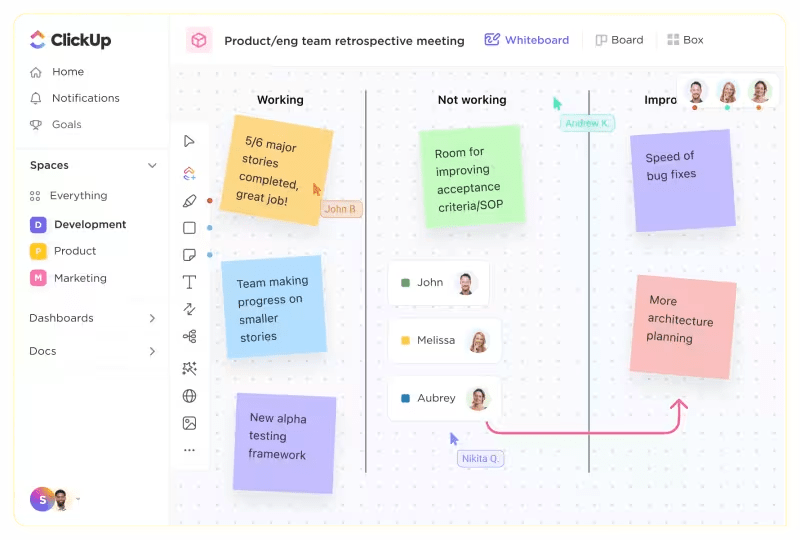

A lean project management platform like ClickUp can act as your guide. It provides visual tools to track each step of the process and helps you strengthen the ethos of transparency, open communication, enhanced productivity, and accurate work management.

Let’s look at various ClickUp tools and their role in implementing Kaizen in your business:

Mastering operational excellence is not easy as it requires a deep conceptual understanding of Kaizen and applying it to real-world business scenarios. Here are the key steps for implementing Kaizen:

Step 1: Identify areas for improvement

Brainstorm as a team to pinpoint processes or departments that could most benefit from Kaizen. To start with, you’ll need to address bottlenecks and delays by getting your team’s and consumers’ opinions.

Use ClickUp Forms to get feedback from customers and employees. Create intuitive forms with conditional logic that evolve as people answer. Share them in real-time with ClickUp’s Chat view that lets you @mention people in comments, assign tasks, attach docs, and so much more.

Let’s say your feedback survey reveals that 70% of your customers feel your mobile app search is buggy, and only 10% feel that the home screen loads slowly. You could prioritize fixing the search over the load speed, recruit a team of engineers to solve it, and assign each relevant engineer specific Tasks in ClickUp , like writing new code, running tests, staging it, and finally making it live.

With powerful ClickUp Automations , you can fully control and turn form responses into tasks that plug directly into your workflows.

After selecting your target process, establish specific, measurable, achievable, relevant, and time-bound [SMART] goals for your Kaizen initiative. Use ClickUp Whiteboards to visually capture goals and ensure clarity for the team. Your goals should be clear, concise, and directly tied to the improvements you aim to achieve.

This visual tool allows you to break down overarching goals into smaller, actionable steps, making the path to improvement more manageable and trackable. Use digital post-its to write down idea topics, map them further into sub-topics, and assign team members tasks to find solutions.

Step 2: Build your Kaizen team

Assemble a Kaizen team that represents the diverse perspectives of everyone involved in the target process.

Whiteboards are instrumental in collaboration. Team members from different departments can access the board simultaneously, add their insights, and brainstorm improvement ideas in real time.

A centralized platform such as ClickUp ensures everyone is on the same page and that valuable contributions from all areas of expertise are considered. Involve a leader who can provide the resources, make decisions, and cultivate the advocacy necessary for the Kaizen initiative to thrive.

Having a leader on board rings true to Kaizen’s philosophy as they actively participate in discussions and brainstorming sessions, sending a strong message of commitment from leadership.

Step 3: Gather information [Genchi Genbutsu]

Physically observe the current process in action. Capture key observations, bottlenecks, and pain points through photos, notes, and annotations by directly embedding them on the whiteboard.

This is known as taking a Gemba Walk, which means going to places where work is taking place to observe and identify areas of improvement.

Using ClickUp Table View , create a digitally accessible spreadsheet to record data you’ve gathered about the current process, such as cycle times, error rates, and customer feedback. You can directly link this to relevant SMART goals on your whiteboard.

Step 4: Analyze the current state

Use the visual steam mapping method on your whiteboard software to map out each process step, highlighting the flow of action, information transfer, and potential waste [Muda].

Use shapes and sticky note features to represent different process stages and visually identify inefficiencies.

For specific bottlenecks, use the 5 Whys technique directly on the whiteboard. Ask ‘Why?’ five times to delve deeper and identify the root cause of problems. You can comment on the whiteboard or ask for clarification by communicating openly on ClickUp Chat.

Step 5: Envision the ideal state

Explore different approaches through collaborative drawing tools, allowing team members to sketch out potential solutions and workflows.

Try ClickUp Mind Maps , idea trees, and other visual formats to generate creative solutions for eliminating waste and simplifying the process.

Benchmarking research can also be visually incorporated. Compile findings from competitor analyses and industry best practices, allowing the team to compare their current process against external benchmarks. Visualize competitor workflows and best practices side-by-side with their process map. The team can identify areas for improvement and draw inspiration for more innovative solutions.

Step 6: Design and pilot the improvement

Collaborate on a clear action plan outlining specific improvement steps, timelines, and responsible individuals. You can make an action plan on the whiteboard or use a pre-built one that’s ready-to-use and fully customizable, like the ClickUp Action Plan Template .

This whiteboard template goes beyond basic action plans, providing features tailored explicitly for the Kaizen methodology:

- Track progress efficiently with user-defined statuses that reflect your Kaizen workflow stages [e.g., ‘Identified Waste,’ ‘Brainstorming Solutions,’ ‘Pilot Testing’]

- Categorize tasks and add relevant attributes specific to your Kaizen plan. This allows you to visualize areas for improvement [e.g., ‘Muda Type’], responsible teams, and improvement ideas, all within the same view

- Start with the Kaizen template and build out your workflow using List, Gantt, Workload, Calendar, and other flexible ClickUp Views to manage your improvement journey seamlessly

- Strengthen your Kaizen efforts with features like comment reaction s for quick feedback, nested subtasks for breaking down complex improvements, assigning tasks to multiple team members, and priority labels to keep critical actions at the forefront

Step 7: Standardize, measure, and continuously improve

Once a successful improvement is verified, document the revised process and establish it as the new standard on your whiteboard.

Use ClickUp Dashboards to track product management KPIs and metrics and observe the effectiveness of implemented changes. You can also track deadlines, manage tasks, observe workload, and see who’s working on what in real time.

Encourage ongoing feedback from team members using comments and discussions on the whiteboard. Keep the Kaizen process visible and adaptable to bring alive a culture of continuous improvement.

A Kaizen event is an intensive workshop focused on rapidly improving a specific process within your organization.

Here are some tips for preparing for a Kaizen event:

- Appoint a facilitator: A facilitator ensures the team works toward the desired outcome, provides guidance, and ensures the event’s success. Make sure the facilitator is familiar with the Kaizen process and tools

- Set the scope : Define the scope and limits of the event and include language about what will not be addressed. A clear and realistic scope that aligns with the organization’s strategic objectives is key

- Assemble the team: Choose team members from relevant departments, including people who provide input and receive output from the area, subject matter experts, and someone who’s not directly involved in the process

- Define success: Set realistic expectations about what can be accomplished within a specific timeframe, financial limits, and results that may be achieved

- Provide training: Kaizen facilitators generally go through training and certification before attempting a Kaizen project

- Plan for follow-up: A feedback loop is necessary to ensure the standards created by the event are being followed. Team members measure and record details that characterize the expected improvements with process improvement templates

Get set to host your Kaizen event and see continuous workflow improvements.

Leadership is crucial to the success of Kaizen implementation not only in manufacturing but also in establishing lean principles in software development .

Senior leaders are responsible for setting the stage for Kaizen, providing support and resources, and creating an environment for positive change.

They often use the Hoshin Kanri approach [a top-down strategy that involves management setting goals and employees implementing them] to align goals and improvement efforts.

Kaizen leaders should also have empathy, digital soft skills, data analytics, a growth mindset, and creativity.

Leaders can demonstrate their commitment to Kaizen by:

- Establishing a common vision and objectives for the team

- Helping and supporting the team with direction and resources

- Demonstrating the desired leadership behaviors

- Engaging and motivating team members

- Developing people’s skills and creating a culture of continuous improvement

- Attending regular project meetings and being present for the team

- Listening for input on challenges or slowdowns

As we’ve covered, implementing Kaizen in your manufacturing process isn’t easy.

However, by equipping you with a step-by-step guide, Kaizen event prepping tips, and defining the role of leadership, we hope we’ve driven the process home.

Here are some key success factors for Kaizen implementation:

- Data analysis: Kaizen is data-driven, so decisions are based on facts, not opinions. It’s important to collect as much accurate data as possible before making a decision

- Employee engagement: Involve employees at all levels of the organization in the Kaizen improvement process to increase engagement and morale, which can lead to better retention rates and increased productivity

- Morale: Strong morale is a crucial step to achieving long-term productivity and efficiency, and Kaizen makes it a foundational task to keep in touch with employee morale

- An open mind: Management and employees need an open mind for Kaizen to work. Kaizen can be a significant change from the way people are used to doing things, and the constant performance analysis may seem pointless at times

Kaizen offers a powerful framework for optimizing processes, increasing efficiency, and achieving long-term success.

Here’s a breakdown of the key benefits and impactful outcomes organizations can expect when using Kaizen:

- Waste reduction [Muda]: This philosophy identifies and eliminates waste in all its forms [e.g., time, motion, overproduction], leading to streamlined processes and improved resource utilization

- Shorter lead times: By eliminating bottlenecks and inefficiencies, this philosophy helps reduce cycle times, allowing products or services to reach customers faster

- Reduced defects and errors: Focus on continuous improvement naturally leads to fewer defects and errors in products or services, enhancing overall quality

- Enhanced customer experience: Faster lead times, fewer errors, and a commitment to ongoing improvement contribute to a more positive customer experience

- Increased customer loyalty: By consistently delivering high-quality products and services, Kaizen helps build customer loyalty and trust

- Problem-solving skills: By actively participating in Kaizen events and brainstorming sessions, employees develop valuable problem-solving and critical-thinking skills

- Innovation and creativity: Kaizen fosters a culture of innovation and creativity where employees are encouraged to think outside the box and propose new ideas

- Adaptability and flexibility: By embracing continuous improvement, organizations become more adaptable and flexible, allowing them to respond effectively to changing market demands

- Sustainability: This philosophy promotes a sustainable approach to business by focusing on resource optimization and waste reduction, contributing to a more environmentally responsible operation

Kaizen is more than an arsenal of philosophical strategies and processes; it also includes tools to equip your organization to achieve lasting results.

We’ve already covered some of these above, such as Value Stream Mapping [VSM], 5 Whys Analysis, and Gemba Walks.

Here are two more that can help you build robust operational workflows in your organization:

- Inventory control techniques: Strategies like Just-in-Time [JIT] aim to minimize inventory holding costs by receiving materials only when they are needed for production. This reduces storage space requirements, frees up working capital, and helps eliminate waste associated with excess inventory

- Kanban boards: Kanban boards are visual workflow management systems that use cards to represent tasks in various agile workflow stages [e.g., To Do, In Progress, Done]. They improve transparency, limit work in progress [WIP] to avoid bottlenecks, and provide a visual overview of workflow progress

ClickUp also offers a range of built-in digital tools to streamline your Kaizen implementation.

- Consolidate all your Kaizen project information, from brainstorming notes to process maps, in a central, searchable location. Create dedicated ClickUp Docs for each Kaizen event, capturing the entire improvement lifecycle

- Break down your Kaizen action plan into actionable tasks with clear deadlines and assignees. The ClickUp List view provides a clear overview of all tasks associated with your Kaizen initiative, ensuring everyone stays on track and accountable

- Define clear ClickUp Goals for your Kaizen events and establish dependencies between tasks to ensure a logical workflow and identify potential roadblocks

- Automate repetitive tasks within your Kaizen workflow using ClickUp Automations. For example, automatically assign tasks based on triggers or move completed tasks to a designated archive folder

Kaizen is a broad philosophy and an even more comprehensive process with a number of implications.

This blog post is just the tip of the iceberg. To know more about this, here are some helpful books and study materials on the topic:

- The Toyota Way by Jeffrey K. Liker: A book on Toyota Production System [TPS], the Origin of Kaizen Principles

- Kaizen: The Method for Continuous Improvement by Robert Maurer: A resourceful book on applying Kaizen to personal habits and daily routines

- Healthcare Kaizen: New Ideas for Improving Quality, Safety, and Efficiency in Health Care by David P. Racht & Jason P. A. Duncan: This book specifically applies Kaizen principles to the healthcare sector, offering practical case studies and guidance for improving patient care

- The Kaizen Institute: A great study resource, The Kaizen Institute is a global consulting firm specializing in continuous improvement. They offer a wealth of resources on their website, such as articles, case studies, white papers, and even online courses to enhance your knowledge

This journey of continuous improvement doesn’t have to be complex. Incorporating Kaizen principles and using the right tools can empower your teams to make significant strides.

ClickUp, with its suite of collaborative features and visual tools, such as ClickUp Whiteboards, ClickUp Dashboards, ClickUp Forms, and several customizable templates, can be your central hub for taking on Kaizen initiatives and excelling at them.

Sign up for ClickUp today and start optimizing your business processes!

Questions? Comments? Visit our Help Center for support.

Receive the latest WriteClick Newsletter updates.

Thanks for subscribing to our blog!

Please enter a valid email

- Free training & 24-hour support

- Serious about security & privacy

- 99.99% uptime the last 12 months

- Free Project Management Software

- Agile Project Management Software

- Project Management Software for Nonprofits

- Organization Apps to Boost Productivity

- Resource Management Software

- Monday Review

- ClickUp Review

- Monday Pricing

- ClickUp Pricing

- Wrike Pricing

- Asana Pricing

- Smartsheet Pricing

- Teamwork Pricing

- Airtable Pricing

- Scoro Pricing

- Asana vs Monday

- ClickUp vs Monday

- Wrike vs Asana

- Trello vs Asana

- ClickUp vs Asana

- What is Agile Project Management?

- Key Benefits of Agile Methodology

- Most Important Agile Metrics

- Agile Manifesto: Values and Principles

- Agile Project Management Certifications

What is Kaizen? Process, Examples, Principles

Most businesses experience failure at different levels and for different reasons. With the Kaizen program and methods, an organization can rise above these failures and become more productive in its activities.

Kaizen involves process changes that can be gradual but will eventually cause big organizational changes. The principles of Kaizen, if implemented properly, will inevitably result in notable improvement within the organization.

This article will expose you to what Kaizen means, Kaizen examples, Kaizen events, and principles you can implement to cause the required changes and potential improvements in your organization.

What is Kaizen?

Kaizen comes from the Japanese words for good and change, change for the better, or improvement. From the philosophical perspective, Kaizen promotes a mindset where small incremental changes ultimately create a notable impact over time.

As a methodology, Kaizen improves certain areas in an organization by engaging top management and front-line employees to make notable daily changes, conscious that small incremental improvements can yield big results.

Japanese manufacturers first endorsed Kaizen as a vital and foundational business philosophy after World War II.

In the business world, Kaizen refers to a mindset where continuous improvement is experienced in the organization through notable gradual improvements.

The Kaizen theory has been proven relevant across various fields and can apply to real-life situations. This theory is considered the major building block of lean manufacturing and lean production in the manufacturing process.

Positive elements such as teamwork, personal discipline, improved morale, quality circles, and suggestions for improvement are necessary for successful Kaizen implementation. They make up the Kaizen framework.

Companies use Kaizen blitz or events as a short-term approach to reducing waste and production costs.

Compared to other Kaizen activities, which focus on fundamental changes over a long period, a Kaizen event is a starting point for continuous improvement designed to deliver the desired results in a particular focus area through many small changes.

What are the Main Principles and Elements of Kaizen?

Since management usually expects immediate results from work done or regarding the execution of projects, implementing the Kaizen theory is almost impossible.

If you want to maximize the advantages of Kaizen, you must understand the principles and elements surrounding it and how to apply them.

1. Management Commitment

A major reason Kaizen's implementation fails is primarily the lack of support and other notable actions from leaders in the organization.

The top management of an organization is vested with the most important responsibility of ensuring that the Kaizen approach is implemented, followed by every manager and then the rank-and-file employees.

When the top management in an organization displays a long-term commitment to continuous improvement, the managers will inevitably follow through on the Kaizen initiative, and the employees will personally cultivate a Kaizen mindset.

2. Employee Empowerment

Employees naturally get acquainted with the best possible ways to improve how the job is done. Organizational leaders should create a work-friendly environment where employees can feel empowered to contribute and bring up suggestions concerning the work.

Creating a work-friendly environment ensures that various suggestions for improvements can come from the different levels and ranks within the organization.

Leaders will boost their morale and confidence by encouraging workers to add value to the organization through their suggestions and contribution.

This strategy gives every individual in the organization a sense of responsibility and ownership of continuous improvement efforts, which will inevitably result in successfully implementing the Kaizen philosophy.

3. Gemba Walk

The achievement of operational efficiency started when the actual task was stated to be executed and not from the discussion in a conference room.

A Gemba Walk is derived from the term Gembutsu or Gemba, which means “the real place” normally performed by a manager to review or learn how a particular process works or functions and acquire in-depth information about workers and the work's continuous improvement.

Gemba Walk checklists serve as a useful guide for observing the relevant questions to be asked to determine the source of the problem and the next steps to take regarding finding solutions to these problems.

4. 5S Principles

One of the biggest challenges that have affected continuous improvement is assuming new ideas or ways of doing things will fail and holding on to old practices and methods of carrying out work.

The 5S Principles aim to improve workplace efficiency and effectiveness by successfully developing new ideas and methods to eliminate waste in the organization’s activities.

Organizations should not hold on to the mindset that a principle, method, or idea that worked previously means it will continue its work because that is not always the case.

Here are the 5S principles:

- Safety & Security

- Waste elimination

- Increased efficiency

- Low implementation cost for high-impact performance

- Development of a collaborative mindset among co-workers

Why Do Manufacturing Businesses Use Kaizen?

1. eliminates waste.

The Kaizen approach is very popular in the world of manufacturing businesses because of its notable principle of waste elimination and incremental improvements. These principles are useful to factory floors for a range of products.

Kaizen helps manufacturing businesses cut their production costs and increase their operating income .

2. Increase Competitive Advantage

Manufacturing businesses use Kaizen to boost their competitive advantage. The purpose of all Kaizen continuous improvement and changes is to produce high-quality products faster to gain a competitive advantage over their competitors.

What is the Kaizen Process?

The Kaizen method is a step-by-step process; the journey of Kaizen’s implementation can only move forward when the right questions are being asked.

The accurate knowledge and clear understanding of the main elements and core principles set the organization for success.

Here are key guide questions you can begin with that show clearly how the Kaizen activities are performed and the process works.

To implement Kaizen, you will have to follow this process.

1. Identify the Problem’s Root Cause

In a situation where an ongoing change-resistant procedure is inadequate or bad, it will be wrong to keep investing resources to solve the wrong problem.

The wise approach is for the leader to drop their assumptions and preconceived notion about who or what they think is wrong. They should ensure proper findings into the issue by implementing Gemba Walk and root cause analysis.

Avoid assuming that new methods will work. You can discover the solution by finding out the root cause of the problem.

As a leader, it is wise to place yourself in a position where you can easily identify quality gaps by communicating personally with workers and observing their work first-hand.

While observing your employee's work, avoid criticizing, finding faults, and apportioning blame on workers. Instead, carefully take note of everything happening without much interference.

You can not get this real-life example of a typical day in operation and the experiences and knowledge acquired through observation from reports.

2. Address the Problem’s Root Cause

With the five why analysis, problem-solving comes easily if these principles are followed accurately.

This analysis helps to determine the root cause of a problem. It can serve as an effective technique in formulating solutions that prevent the recurrence of the identified problem.

This technique is equipped with creative suggestions for workers and supported by relevant information from where work happens. Managers can use it to implement low-cost but high-value improvements that sync with the quality objective of the organization.

3. Ensure Consistent Implementation of Changes

An organization's senior management consultant shows commitment to continuous improvement when it immediately takes action on the small incremental changes and follows through with significant long-term initiatives.

The notable changes should begin with you by personally making adjustments to how you work and carefully taking note of its significant effect on the quality of your output.

Kaizen is relevant to every organization member and not just exclusive to a particular set of people, such as team members alone. It should occur everywhere within the organization, not just on the shop floor.

You can save quality time and money from manual monitoring across various sites and levels of the organization by centralizing Kaizen management.

4. Impact of Continuous Improvement Efforts

While implementing Kaizen principles, most people are impatient . They may give up because they do not instantly see or feel notable differences their seemingly small actions make in the company.

The A3 or 8D reports are ideal documents that managers or leaders in an organization can share with employees because they measure the effectiveness, monitor the performance of implemented changes, and communicate the impact of Kaizen’s principles.

You should note the most impactful solution to know the specific actions the company needs to start, continue or stop taking.

5. How Else Can We Keep Improving?

The journey of continuous improvement is not marked by perfection but by a strong desire for personal and organizational growth.

If you can achieve 50% of your improvement goals, you are doing great; you need to celebrate your wins but never stop there; you must keep improving.

Do not leave issues that arise in the workplace to linger for a long time before you take significant action.

You should be proactive about solving problems in the workplace because Kaizen is an unending process. With these actions, you guarantee continuous improvement in the workplace.

How is 5S Used in the Kaizen System?

The 5S in the Kaizen system shows the concept of continuous improvements and notable actions taken to reduce waste.

1. Sort or Seiri

The first S, which stands for Sort, or Seiri, emphasizes the strong desire to eliminate any unnecessary object or entity clustering the work environment. It serves as a distraction or hindrance to workplace activities and constant improvement.

2. Set in Order or Seition

The second S is focused on effectively organizing useful objects in their rightful place. This action helps increase efficiency, improve productivity and minimize wastage of space and time.

Everything needed to accomplish given workplace tasks is properly arranged in the right place, at the right time, and in the right order.

3. Shine or Seiso