Toyota: a case study

Oct 30, 2014

710 likes | 2.16k Views

Toyota: a case study. Background. Toyota Motor Company was founded in 1937 by the Toyoda family. Business was relatively unsuccessful until Eiji Toyoda introduced the method of lean production after studying Ford’s Rouge plant in Detroit in 1950.

Share Presentation

- lean production

- production system

- product development

- lean production method

- production smoothing enables suppliers

Presentation Transcript

Background • Toyota Motor Company was founded in 1937 by the Toyoda family. • Business was relatively unsuccessful until Eiji Toyoda introduced the method of lean production after studying Ford’s Rouge plant in Detroit in 1950. • This lean production method became known as the Toyota Production System. • The production executive, Taiichi Ohno, successfully helped Toyoda improve his company using this new production method and mode of thinking.

Environment • Cultural • Company as a community: lifetime employment, access to company facilities, seniority-based wages (in return for 1/3 work force layoff in 1946) ; as a return, employees must be more flexible and actively promote interests of company >> Implications: labor = Fixed cost • Economic • Postwar conditions put Japan into a country lacking significant capital, so that Japan had to rely mostly on producing its own technology. • Political • The Ministry of Int’l Trade and Industry (MITI) encouraged Japanese firms to enter the automobile industry despite established competitors from the West by imposing high tariffs discouraging imports and prohibiting foreign ownership. • Japan’s work force, under Western influence after WWII, grew more powerful and more demanding, thus limiting producers’ efforts to reduce labor costs.

Environment (cont.) • Demographical • The domestic market was very small and un-uniform. Thus, goods had to be very tailored to specific consumer taste. E.g. luxury cars for officials, small cars for city residents, etc. • Technological • Commitment to innovation and improvement • Large skilled-labor pool to draw from • Social • Commitment by employees to work

Country Differences? • Western “careers” vs. Japanese “community” • Focus on long-term growth as opposed to short-term profits • More interpersonal relationships with employees, suppliers, and customers

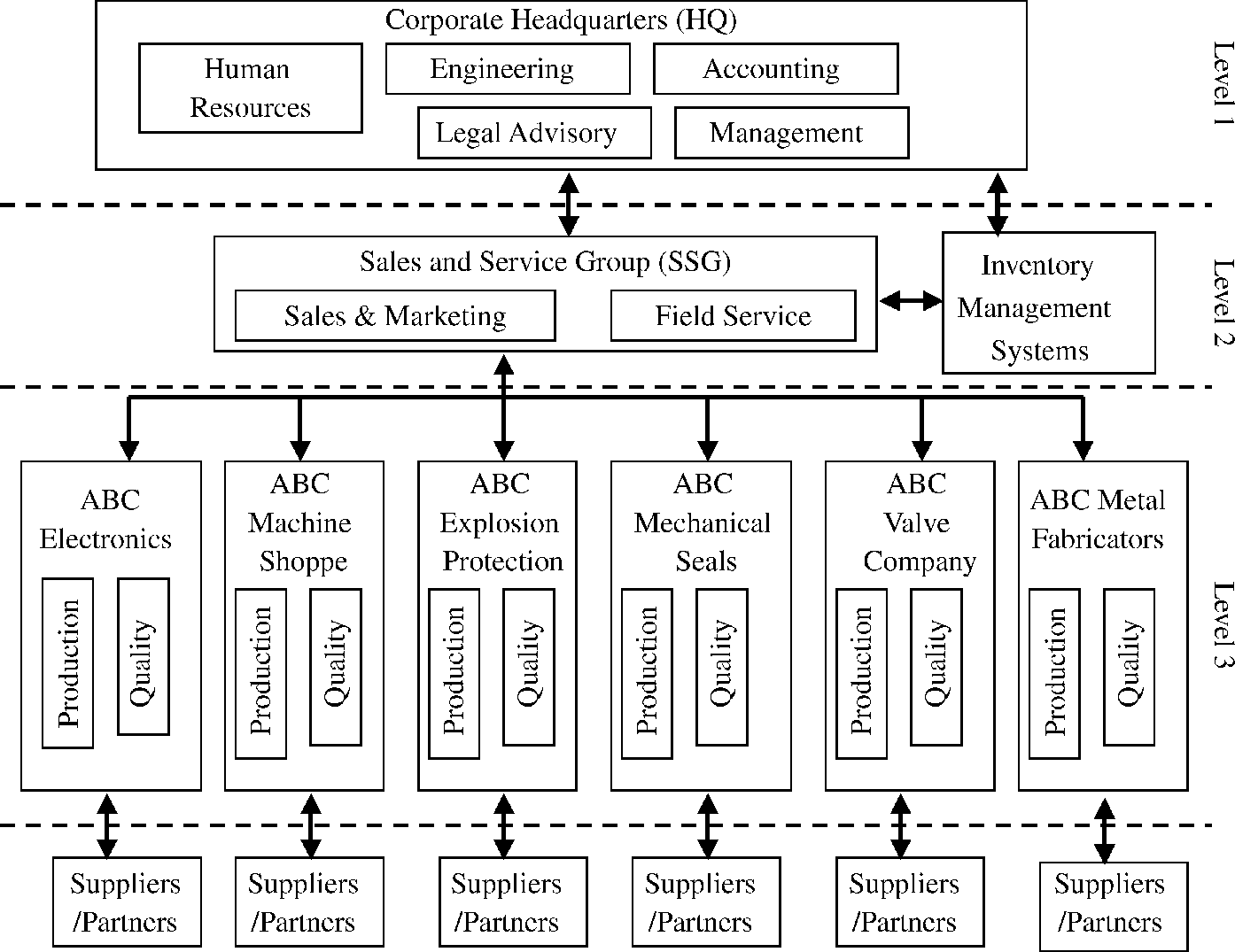

Organizational Structure • Multi-regional lean enterprise • Primarily network structure • Network of suppliers • Network of dealers/distributors • Frequent interaction between all levels of the organization

Strategy – Lean Production • Final assembly plant • Moved from “move the metal” mentality to kaizen • Introduced idea of stopping assembly lines in order to correct problems before continuing • As a result, quality improved and yields are close to 100% • Product development and engineering • Focused on leaders that knew all steps of a process rather than those with highly specialized knowledge; also, skill-building • More emphasis on proactive thinking by employees • Thus, increased productivity, product quality, and responsiveness to changing consumer demand • “quality circles”

Lean Production – in more detail • 2 organizational features: • “Transfer max number of task and responsibilities to those workers actually adding value to the car on the line” • “has in place a system for detecting defects that quickly traces every problem, once discovered, to its ultimate cause” • Thus, need tight teamwork and open communication among workers (comprehensive info display system on electronic displays visible from all work areas) • 4 areas of importance: • Leadership: Toyota’s large-project leader w/power vs. Western coordinator • Teamwork: from many functions, ties with department, and general interest in promoting team, not department • Communication: conflicts resolved in beginning, more people => less people • Simultaneous Development

Competitive Advantages • Reliability • Product variety • Production plants in North America build 2-3 products at a time, as opposed to one by Western firms. • Firms keep models for an average of four years, as opposed to an average of close to ten years by Western companies. • Western companies sell almost twice as many cars of the same model as Japanese firms do.

Suppliers – Lean Production Supply Chain • Organized suppliers into functional tiers • First-tier suppliers: worked together in a product-development team • Second-tier: made individual parts • Encouraged cooperation and communication among first-tier suppliers • In –house supply operations turned into a network of “quasi-independent first-tier supplier companies” • Substantial cross-holdings between Toyota and suppliers, as well as among suppliers themselves even though each supplier is an independent company • Cross- sharing of personnel through • Toyota sending personnel to suppliers to compensate for greater workload • Toyota transferring senior managers to suppliers for top positions • Developed the “just-in-time” (JIT) system, or kanban

Suppliers – Lean Production Supply Chain (cont.) • “market price minus” system, not “supplier cost plus” system • Value analysis reduces costs • Declining prices over life of model due to learning curve • Production smoothing enables suppliers to maintain a constant volume of business • Focus is on long-term relationships that underscores cooperation, teamwork, and gradual mutual improvement, rather than price through bidding as a way to choose a supplier

Consumers • The market began to fragment in the 1960s as cars increased in popularity and became essential household goods. • Marketing executive Shotaro Kamiya focused on building a sales network modeled after Toyota’s supplier network. • Distributors with a “shared destiny”: wholly owned companies or ones in which Toyota held equity • “aggressive selling”: promoted long-term relationship between assembler, dealer, and buyers • Dealer => production system => build-to-order system • Buyers => product development process • Direct calls to households with large database of households and buying preferences • Focus on repeat buyers • Also focus on brand loyalty => “Toyota family” • 5 distribution channels in Japan: Toyota, Toyopet, Auto, Vista, and Corolla • Closer and more familiar relationship between buyer and salesperson • Focus on customer-specified order

Marketing • Door-to-door selling/very customized • Emphasis on “pull” marketing: giving consumers what they want • Tight relationship with previous buyers to keep clients • Sales personnel received intensive training before starting their jobs • Up-to-date and detailed database of consumers helps keep track of trends, interests, and tastes

Competitors • American companies upon which Toyota originally developed many of its own production processes from • GM • Ford • Etc. • Korean companies with planned production • Other Japanese companies, especially Nissan and Honda

Problem • Obstacle: inward focus of Japanese lean producers • Lack the ability to think and act globally rather than from a narrow national perspective • Backlash to Japanese direct investment in North American and Europe, a prominent reason of which is that it creates friction as a result of Japanese corporation biases, mainly two classes of citizenship in their organizations • E.g. keiretsu

Possible Solutions • Appoint native managers to head their manufacturing operations in North America and Europe • Designate native supplier companies as source for certain categories of components • Governments: restrictions on visas for Japanese employees at new facilities and in Europe, strong pressures to attain high levels of domestic content asap • Author suggests: build a truly global personnel system in which new workers from North America, Europe, etc. where a company has design, engineering, and production facilities, are hired in at an early age and given the skills, including language and exposure to management in different regions, needed to become full citizens of the company • Same for suppliers • Need increased transparency

Conclusion – Watch for quality • fear of repetition of Ford’s experience in Britain after 1915 • Wholesale substitution of domestic managers and suppliers, to deal with investment friction, will degrade performance of production system toward the existing level • Evidence that plants that perform best are those with very strong Japanese mgmt presence in early years of operations and those that have moved slowly and methodically to build up their domestic supply base • Need managers and suppliers that understand lean production and are committed to it, mostly Japanese

Financial figures • In fiscal 2003, ended March 31, 2003, Toyota’s consolidated net revenues increased 9.2%, to ¥15.50 trillion, operating income rose 16.3%, to ¥1.27 trillion, and net income was up 34.9%, to ¥750.9 • ROE reached 10.4%, surpassing the short-term target of 10%. • As of March 31, 2003, treasury stock repurchased by the Company totaled ¥1.38 trillion, or 416 million shares, and total shares issued and outstanding—excluding treasury stock—had decreased to 3.45 billion shares. • In fiscal 2003, the Company paid its highest-ever annual dividend—¥36.00 per share, up ¥8.00 from the previous fiscal year.

- More by User

Chapter 5 Case Study: MVC Architecture for Web Applications

Chapter 5 Case Study: MVC Architecture for Web Applications Objectives of This Chapter Overview MVC Basics JDBC A Case Study: On-Line Shopping Application Introduce concepts of MVC design architecture Demonstrate the Java implementation of MVC architecture

1.67k views • 91 slides

Mutualism and Commensalism

Mutualism and Commensalism. 14 Mutualism and Commensalism. Case Study: The First Farmers Positive Interactions Characteristics of Mutualism Ecological Consequences Case Study Revisited Connections in Nature : From Mandibles to Nutrient Cycling. Case Study: The First Farmers.

2.06k views • 45 slides

Nationalisation: A case study of Zambia

Nationalisation: A case study of Zambia. By Ndangwa Noyoo Rhodes University Summer School 13 September 2011. Introduction.

1.22k views • 40 slides

Case Study Analysis

Case Study Analysis. Karen Pelletier Geneice Bassue Lee Dubois James Lowe. History of the Company. Incorporated in 1998 in Delaware, commenced service in 2000 - primary base of operations at JFK in New York.

2.75k views • 30 slides

Water Quality

Water Quality. Intro by Erick Bjorkland Chesapeake Bay Case Study Brandon Powers Created Wetlands by Carol Ann Dulin Saltwater Case Study by Meghan Barron. Clean Water Act.

1.3k views • 75 slides

Case Study Research Manufacturing and Technology Management Research Methodology Workshop 2008

Case Study Research. Outline. What is a case?Why case study research?Designing case studiesExample 1: changes in the spatial organization of high growth start-upsExample 2: the decline of the Cambridgeshire high-tech clusterSummary. Case Study Research. What is a case?. Case Study Research. What is a case?.

1.58k views • 32 slides

The Toyota Recall Crisis: Causes, Contexts, and the Impact on the Global Auto Industry

The Toyota Recall Crisis: Causes, Contexts, and the Impact on the Global Auto Industry. Dr. Jun Zhao Associate Professor of Management College of Business and Public Administration Governors State University Presented at the 30 th IASET Annual Spring conference. The Toyota Recall Crisis.

1.02k views • 21 slides

Study Case : Walt Disney’s & Dennis Hightower

Study Case : Walt Disney’s & Dennis Hightower. Buku : Managing Change; Case & Concept, Todd D. Jick, McGraw Hill, second edition, p.366 - 378. Disney’s Organization. Founded in 1923 by Disney brothers, Walt and Roy, with $500 loan, and had grown by 1987 into an entertainment industry.

2.33k views • 11 slides

The Toyota Production System

The Toyota Production System. Japanese 101. Why study Toyota?. Total annual profit on March 2003 was $8.23 billion- larger than combined earnings of GM, Chrysler and Ford. Profit margin is 8.3 times higher than industry average.

4.68k views • 46 slides

HUD RHIIP Training – PH/HCV

HUD RHIIP Training – PH/HCV. Case Study 3 – Champion Family (Housing Choice Voucher). Champion Case Study:. Same process as Alexander and Bennett Topic presentation Students complete case study Using Appendix C, File Review Checklist Worksheets Students review PHA’s HUD 50058

1.46k views • 94 slides

Nestle Case Study

Nestle Case Study. Group 8: Sohum Mehta, Johannes Matthias, Rahil Poojara, Austin Cunningham, Xiaoya Li. Largest nutrition and foods company in the world Founded and headquarterd in Vevey, Switzerland

2.95k views • 22 slides

NIC Exposure Level Training

NIC Exposure Level Training. Vijayendra Gururao Business Intelligence Consultant. Agenda. Data warehousing Concepts - Day 1 Govt Case Study - Day 2 Defense HR Case study - Day 3 Manufacturing Case Study - Day 4 Data mining - Day 5. What to do about it . 2001. Active. Act.

1.64k views • 139 slides

Case Study Research: Developmental Research

Case Study. What comes to your mind when you hear case study"?. Camila is responsible for . P.21-32Introducing case study researchExperiencing case study researchCompiling case study researchAnalyzing case study researchReporting your results. Ariel is responsible for. Designing case study re

1.48k views • 36 slides

Case Study Congestive Heart Failure

Case Study Congestive Heart Failure. By: Ellinor Lagerberg. Reason for study. Gain knowledge about CHF (congestive heart failure) and its etiology. To understand how nutrition education is applied in acute care for patients with CHF.

7.65k views • 36 slides

Schizophrenia

Schizophrenia. Unfolding Case Study By Amanda Eymard , DNS, RN and Linda Manfrin-Ledet , DNS, APRN. Assigned Reading to be completed prior to case study. Prior to conducting this unfolding case study, students should read the following:

4.3k views • 82 slides

Social Research Methods

Social Research Methods. Case Studies. What is a Case Study?. “ A strategy for doing research which involves an empirical investigation of a particular contemporary phenomenon within its real life context using multiple sources of evidence ” (Robson, 1993, p. 146) A Case Study may be…

1.62k views • 14 slides

Chapter 5 Case Study: MVC Architecture for Web Applications. Objectives of This Chapter. Overview MVC Basics JDBC A Case Study: On-Line Shopping Application Introduce concepts of MVC design architecture Demonstrate the Java implementation of MVC architecture

1.25k views • 91 slides

Randomized Controlled Trial

Randomized Controlled Trial. Subodh S Gupta Dr. Sushila Nayar School of Public Health MGIMS, Sewagram. Progression of Study Design: Clinical Research. Isolated Case Reports Case Series Cross-Sectional study Case-Control Study Cohort Study Randomized Clinical Trial Meta-Analysis

1.74k views • 83 slides

TOYOTA BUSINESS PRACTICES Overview

TOYOTA BUSINESS PRACTICES Overview. Outcome of TBP. TBP Provides Growth & Satisfaction. TOYOTA. Toyota Members. Business Partners. Combining our efforts and attaining mutual growth. Mutual trust through successful business. Achieving greater challenges Sharing the accomplishments

5.26k views • 59 slides

Case study research

Case study research. Marie-Louise Barry. Use of different strategies.

1.77k views • 79 slides

adidas Case Study

adidas Case Study. By: Ray Moorman Dan McLinden Tom Anderson Kyle McDaniel Jeremy Smiley. Primary Question for adidas.

4.4k views • 37 slides

- My presentations

Auth with social network:

Download presentation

We think you have liked this presentation. If you wish to download it, please recommend it to your friends in any social system. Share buttons are a little bit lower. Thank you!

Presentation is loading. Please wait.

To view this video please enable JavaScript, and consider upgrading to a web browser that supports HTML5 video

A CASE STUDY ON TOYOTA PRODUCTION SYSTEM

Published by Gyles Hicks Modified over 8 years ago

Similar presentations

Presentation on theme: "A CASE STUDY ON TOYOTA PRODUCTION SYSTEM"— Presentation transcript:

Presented by Art Smalley President Art of Lean, Inc.

Lean Supply Chains Chapter Fourteen McGraw-Hill/Irwin

Fundamentals of Operations Management 4e© The McGraw-Hill Companies, Inc., –1 Managerial Issues Using JIT as a tool for controlling the flow of materials,

JIT, TPS, and Lean Operations

Chapter 3 Planning for Production. Objectives Product oriented manufacturing systems versus people oriented manufacturing systems. Manufacturing smaller.

Toyota’s lean management Harel cohen Maxim shulman.

Just-in-Time and Lean Systems

Operations Management Just-in-Time Systems Supplement 12

JIT/Lean Production. ©2006 Pearson Prentice Hall — Introduction to Operations and Supply Chain Management — Bozarth & Handfield Chapter 15, Slide 2 Some.

Chapter 16 - Lean Systems Focus on operations strategy, process, technology, quality, capacity, layout, supply chains, and inventory. Operations systems.

JIT and Lean Operations. MRP (push) and JIT (pull) system PULL SYSTEM PUSH SYSTEM A PUSH system where material is moved on to the next stage as soon as.

JIT/Lean Production Chapter 13.

Benefits of Lean Manufacturing: To benefit from Lean Manufacturing, the processes must be maintained consistently and correctly. Everyone involved must.

The Value of Lean Thinking Presented by: Brian D Krichbaum Process Coaching Incorporated.

Lean for Process Manufacturing QAD Midwest User Group Meeting Stephen Dombroski – September 2011.

JUST IN TIME. Just in Time Getting the right quantity of goods at the right place at the right time.

Operations Management BA 301 – Spring 2003 Just-in-Time Systems Supplement 12.

Billy Brown, Bridget Lawson, Dev Shah, Jason Smeak, and Craig Taylor

JIT and Lean Operations

1 Chapter 16 Just-In-Time Systems. 2 JIT/Lean Production Just-in-time: Repetitive production system in which processing and movement of materials and.

About project

© 2024 SlidePlayer.com Inc. All rights reserved.

Academia.edu no longer supports Internet Explorer.

To browse Academia.edu and the wider internet faster and more securely, please take a few seconds to upgrade your browser .

Enter the email address you signed up with and we'll email you a reset link.

- We're Hiring!

- Help Center

Case Analysis, Toyota: "The Lean Mind" 70 Years of innovation

This case study aims to reveal the reasons for Toyota's success and make its experience guide the developing brands to success.

Related Papers

helen turner

Long Range Planning

Peter J. Buckley

Mossimo Sesom

Deborah Nightingale

This Transition-To-Lean Guide is intended to help your enterprise leadership navigate your enterprise’s challenging journey into the promising world of “lean.” You have opened this guide because, in some fashion, you have come to realize that your enterprise must undertake a fundamental transformation in how it sees the world, what it values, and the principles that will become its guiding lights if it is to prosper — or even survive — in this new era of “clock-speed” competition. However you may have been introduced to “lean,” you have undertaken to benefit from its implementation.

Ayesha Majid , Yahya Rehman

Toyota is a name almost everyone is familiar with. It has been the market leader in automobiles specially hybrid and electric automobiles. It has been operational in Pakistan since 1989. Toyota is a one of a kind Japanese multinational automotive manufacturer. As of September 2018, it was the sixth largest company in the world in terms of revenue. The economic conditions however have not been very favorable for the automotive industry. The economy of Pakistan and the consistent increase in dollar rates has taken a huge toll on the sales of the multinational manufacturer. Focus group analysis show that majority of the people preferred Honda over Toyota due to several reasons including near to none change in the designs of Toyota Corolla’s variants. Another factor was that Toyota was seen more as a car for the rural areas which was best suited for a rugged terrain. Although the general perception is that Toyota has better car suspension and fuel efficiency, people would still prefer Honda and other Japanese cars. Respondents said that advertisements played a crucial role but they do not compel the customer to buy a product like a car, there are other factors that are taken under consideration. Pakwheels and olx were the first two online platforms that they mentioned when asked about their go to online source. Family and friends advice played a major role in deciding which car to buy. According to the research conducted by our group through questionnaire, a regression was done and seen that the general perception that a reduction in prices will increase sales was not true because people usually associate low prices with low quality products. According to the regression, only advertisement and product have a significant result. All the variables are positively correlated with each other and less than one and positive indicating a formative relationship to the dependent variable. Branding has an insignificant positive relationship with purchase intention because consumers are only considering three competitors; Honda, Suzuki and Japanese cars.

Volume III of this guide may be used as an in-depth reference source for acquiring deep knowledge about many of the aspects of transitioning to lean. Lean change agents and lean implementation leaders should find this volume especially valuable in preparing their organizations for the lean transformation and in developing and implementing an enterprise level lean implementation plan. The richness and depth of the discussions in this volume should be helpful in charting a course, avoiding pitfalls, and making in-course corrections during implementation. We assume that the reader of Volume III is familiar with the history and general principles of the lean paradigm that are presented in Volume I, Executive Overview. A review of Volume II, Transition to Lean Roadmap may be helpful prior to launching into Volume III. For those readers most heavily involved in the lean transformation, all three volumes should be understood and referenced frequently.

Loading Preview

Sorry, preview is currently unavailable. You can download the paper by clicking the button above.

- We're Hiring!

- Help Center

- Find new research papers in:

- Health Sciences

- Earth Sciences

- Cognitive Science

- Mathematics

- Computer Science

- Academia ©2024

Implementation of Total Quality Management (TQM): Toyota Case Study

- To find inspiration for your paper and overcome writer’s block

- As a source of information (ensure proper referencing)

- As a template for you assignment

Introduction

Implementation of tqm in toyota, tqm practices in toyota, benefits of tqm in toyota, examples of tqm in toyota, toyota quality management, toyota tqm implementation challenges.

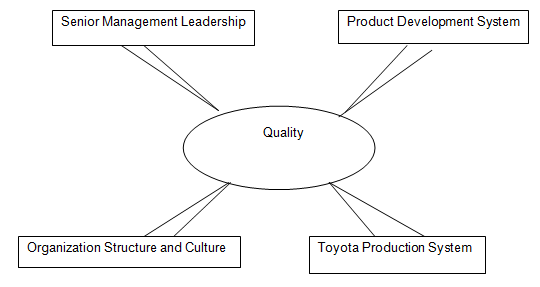

The Toyota Corporation case study report is based on the implementation of total quality management (TQM) meant to improve the overall performance and operations of this automobile company. TQM involves the application of quality management standards to all elements of the business.

It requires that quality management standards be applied in all branches and at all levels of the organization. The characteristic of Toyota Corporation going through the total quality process is unambiguous and clear.

Toyota has limited interdepartmental barriers, excellent customer and supplier relations, spares time to be spent on training, and the recognition that quality is realized through offering excellent products as well as the quality of the entire firm, including personnel, finance, sales, and other functions.

The top management at Toyota Corporation has the responsibility for quality rather than the employees, and it is their role to provide commitment, support, and leadership to the human and technical processes (Kanji & Asher, 1996).

Whereas the TQM initiative is to succeed, the management has to foster the participation of Toyota Corporation workers in quality improvement and create a quality culture by altering attitudes and perceptions towards quality.

This research report assesses the implementation of TQM and how Toyota manages quality in all organization management systems while focusing on manufacturing quality. The report evaluates the organization management elements required when implementing TQM, identifies, and investigates the challenges facing Quality Managers or Executives in implementing Quality Management Systems.

In order to implement TQM, Toyota corporations focused on the following phases:

- The company extended the management responsibility past the instantaneous services and products

- Toyota examined how consumers applied the products generated, and this enabled the company to develop and improve its commodities

- Toyota focused on the insubstantial impacts on the procedures as well as how such effects could be minimized through optimization

- Toyota focused on the kaizen (incessant process development) in order to ensure that all procedures are measurable, repeatable, and visible.

The commitment from business executives is one of the key TQM implementation principles that make an organization successful. In fact, the organizational commitment present in the senior organizational staff ranges from top to lower administration. These occur through self-driven motives, motivation, and employee empowerment. Total Quality Management becomes achievable at Toyota by setting up the mission and vision statements, objectives, and organizational goals.

In addition, the TQM is achievable via the course of active participation in organizational follow-up actions. These actions denote the entire activities needed and involved during the implementation of the set-out ideologies of the organization. From Toyota Corporation’s report, TQM has been successful through the commitment of executive management and the organizational workforce (Toyota Motor Corporation, 2012).

Through inventory and half the bottlenecks at half cost and time, the adopters of TMS (Toyota Management System) are authorized to manufacture twice above the normal production. To manage the quality in all organizational management systems, the Toyota Production System incorporates different modernisms like strategy or Hoshin Kanri use, overall value supervision, and just-in-time assembly.

The amalgamation of these innovations enables Toyota to have a strong competitive advantage despite the fact that Toyota never originated from all of them. The 1914 Henry Ford invention relied on the just-in-time production model. The Ford system of production, from a grand perspective, warrants massive production, thus quality (Toyota Motor Corporation, 2012).

Kanji and Asher (1996) claim that to manage the minute set of production necessitated by the splintered and small post-war marketplaces, the JIT system focuses on the motion and elimination of waste materials. This reduces crave for work-in-process inventory by wrapping up the long production lines. Toyota Corp wraps the production lines into slashed change-over times, a multi-trained workforce that runs manifold machines, and new-fangled cells into a U shape.

When supplementing the just-in-cells, the system of kanban is employed by the Toyota Corporation to connect the cells that are unable to integrate physically. Equally, the system helps Toyota integrate with other external companies, consumers, and suppliers.

The TQM and the creativity of Toyota proprietors both support the quality at the source. The rectification and discovery of the production problems require the executives to be committed. At the forefront of Toyota operations, the managers integrate a number of forms of operational quality checks to ensure quality management at all levels.

The uninterrupted tests help the Toyota workforce engaging in the assembly course to scrutinize the value of apparatus, implements, and resources utilized in fabrication. The checks help in the scrutiny of the previously performed tasks by other workers. However, the corporation’s own test enables the workers to revise their personal advances in the assembly course.

The Toyota process owners set up the mistake-proofing (Poka-yoke) procedures and devices to capture the awareness of management and involuntarily correct and surface the augmenting problems. This is essential for the critical production circumstances and steps that prove impractical and tricky for Toyota employees to inspect.

Nevertheless, the policy deployment system decentralizes the process of decision-making at Toyota. This context of implementing Total Quality Management originates from Hoshin Kanri’s management by objective (MBO).

This aspect becomes more advantageous to Toyota when dealing with quality management. The system initially puts into practice the coordinated approach and provides a clear structure for the suppliers, producers, and consumers through inter-organizational cost administration. Moreover, Toyota executives can solve the concurrent delivery, cost, and quality bottlenecks, thus replacing and increasing the relatively slow accounting management mechanisms.

Customer focus that leads to the desired customer satisfaction at Toyota Company is one of the major success factors in TQM implementation. For every business to grow, it should have understanding, reliable, and trustworthy customers. The principle of customer satisfaction and focus has been the most presently well-thought-out aspect of Toyota’s manufacturing quality.

The TQM may characteristically involve total business focus towards meeting and exceeding customers’ expectations and requirements by considering their personal interests. The mission of improving and achieving customer satisfaction ought to stream from customer focus.

Thus, when focusing on manufacturing quality, this aspect enhances TQM implementation. The first priorities at Toyota are community satisfaction, employees, owners, consumers, and mission. The diverse consumer-related features from liberty. The concern to care is eminent in Toyota Corporation during manufacturing.

Toyota has three basic perspectives of TQM that are customer-oriented. These are based on its manufacturing process traced back to the 1950s. The strategies towards achieving quality manufacturing, planning, and having a culture towards quality accomplishment are paramount for TQM implementation to remain successful. To enhance and maintain quality through strategic planning schemes, all managers and employers must remain effectively driven.

This involves training workers on principles concerning quality culture and achievement. Scheduling and planning are analytical applications at Toyota Company that purposes in assessing customer demand, material availability, and plant capacity during manufacturing.

The Toyota Corporation has considerable approaches that rank it among the successful and renowned implementers of TQM. From the inherent and designed structure of Toyota, it becomes feasible to comprehend why quality manufacturing is gradually becoming effective. The inspection department is responsible for taking corrective measures, salvaging, and sorting the desired manufactured product or service quality.

The Toyota Corporation also has a quality control system that is involved in determining quality policies, reviewing statistics, and establishing quality manuals or presentation data. Furthermore, quality assurance is one of the integral principles in quality implementation that is practically present at Toyota. The quality assurance and quality inspectors throughout the Toyota Company structure also manage research and development concerning the quality of manufactured products and services.

The Toyota production and operations management system is similarly dubbed as the managerial system. In fact, in this corporation, operational management is also referred to as the production process, production management, or operations (Chary, 2009). These simply incorporate the actual production and delivery of products.

The managerial system involves product design and the associated product process, planning and implementing production, as well as acquiring and organizing resources. With this broad scope, the production and operation managers have a fundamental role to play in the company’s ability to reach the TQM implementation goals and objectives.

The Toyota Corporation operations managers are required to be conversant and familiar with the TQM implementation concepts and issues that surround this functional area. Toyota’s operation management system is focused on fulfilling the requirements of the customers.

The corporation realizes this by offering loyal and express commodities at logical fees and assisting dealers in progressing commodities proffered. As Slack et al. (2009) observed, the basic performance objectives, which pertain to all the Toyota’s operations, include quality, speed, flexibility, dependability, and cost. Toyota Company has been successful in meeting these objectives through its production and operation functions.

Over several decades, Toyota’s operational processes and management systems were streamlined, resulting in the popularly known Toyota Production System. Although the system had been extensively researched, many companies, such as Nissan, experienced difficulties in replicating TPS.

The TPS was conceived when the company realized that producing massive quantities from limited product lines and ensuring large components to achieve maximum economies of scale led to flaws. Its major objectives were to reduce cost, eliminate waste, and respond to the changing needs of the customers. The initial feature of this system was set-up time reduction, and this forms the basis of TQM implementation.

At Toyota Corporation, quality is considered as acting responsibly through the provision of blunder-gratis products that please the target clientele. Toyota vehicles are among the leading brands in customer satisfaction. Due to good quality, its success has kept growing, and in 2012, the company was the best worldwide. Moreover, Toyota has been keen on producing quality vehicles via the utilization of various technologies that improve the performance of the vehicles.

While implementing TQM, Toyota perceives speed as a key element. In this case, speed objective means doing things fast in order to reduce the time spent between ordering and availing the product to the customer.

The TPS method during processing concentrates on reducing intricacy via the use of minute and uncomplicated machinery that is elastic and full-bodied. The company’s human resources and managers are fond of reorganizing streams and designs to promote minimalism. This enhances the speed of production.

Another objective during TQM implementation is dependability. This means timely working to ensure that customers get their products within the promised time. Toyota has included a just-in-time production system comprised of multi-skilled employees who work in teams. The kanban control allows the workers to deliver goods and services as promised. Advancing value and effectiveness appears to be the distress for administrators, mechanical specialists, and other Toyota human resources.

During TQM implementation, Toyota responds to the demands by changing its products and the way of doing business. Chary (2009) argues that while implementing TQM, organizations must learn to like change and develop responsive and flexible organizations to deal with the changing business environment.

Within Toyota plants, this incorporates the ability to adopt the manufacturing resources to develop new models. The company is able to attain an elevated degree of suppleness, manufacturing fairly tiny bunches of products devoid of losses in excellence or output.

The organizational hierarchy and job descriptions also determine the successful implementation of the TQM. Toyota is amongst the few companies whose organizational structure and task allocation have proved viable in TQM implementation. The company has three levels of management. See the diagram below.

Management hierarchy

Despite the hierarchy and task specification, employees are able to make independent decisions and take corrective measures when necessary to ensure quality during production. Team working is highly encouraged at Toyota Corporation, and this plays a significant role during TQM implementation. All stakeholders are incorporated in quality control initiatives to ensure client demands are satisfied.

However, all employees are required to carry out their assigned tasks, and the management closely supervises the ways of interactions between workers. The management ensures that the manufacturing lines are well-built and all employees are motivated to learn how to improve the production processes.

Toyota is among the few manufacturers in the complete automobile industry that consistently profited during the oil crisis in 1974. The discovery was the unique team working of the Japanese that utilized scientific management rules (Huczynski & Buchanan, 2007).

The joint effort in Japan, usually dubbed Toyotaism, is a kind of job association emphasizing ‘lean-assembly.’ The technique merges just-in-time production, dilemma-answering groups, job equivalence, authoritative foremost-streak administration, and continued procedure perfection.

Just-in-time (JIT) assembly scheme attempts to accomplish all clients’ needs instantly, devoid of misuse but with ideal excellence. JIT appears to be dissimilar from the conventional functional performances in that it emphasizes speedy production and ravage purging that adds to stumpy supply.

Control and planning of many JIT approaches are concerned directly with pull scheduling, leveled scheduling, kanban control, synchronization of flow, and mixed-model scheduling (Slack et al., 2009).

Toyota appears to be amongst the principal participants in changing Japan to a kingpin in car production. Companies, which have adopted the company’s production system, have increased efficiency and productivity. The 2009 industrial survey of manufacturers indicates that many world-class firms have adopted continuous-flow or just-in-time production and many techniques Toyota has been developing many years ago.

In addition, the manufacturing examination of top plant victors illustrates that the mainstream them utilize lean production techniques widely. Thus, team-working TPS assists Toyota Corporation in the implementation of TQM.

Executives and Quality Managers face some challenges while implementing Quality Management Systems in organizations. In fact, with a lack of the implementation resources such as monetary and human resources in any organization, the implementation of TQM cannot be successful. Towards the implementation of programs and projects in organizations, financial and human resources have become the pillar stones.

The approach of TQM impels marketplace competence from all kinds of organizational proceeds to ensure profitability and productivity. To meet the desired results in TQM implementation, an organization ought to consider the availability of human and financial resources that are very important for the provision of an appropriate milieu for accomplishing organizational objectives.

In the case of Toyota, which originated and perfected the philosophy of TQM, the Executives, and Quality Managers met some intertwined problems during TQM implementation. The flaw in the new product development is increasingly becoming complicated for the managers to break and accelerate, thus creating reliability problems. Besides, secretive culture and dysfunctional organizational structure cause barriers in communication between the top management, thus, in turn, augmenting public outrage.

The top executives may fail to provide and scale up adequate training to the suppliers and new workforces. As a result, cracks are created in the rigorous TPS system. In addition, a lack of leadership at the top management might cause challenges in the implementation of TQM. Therefore, in designing the organizational structures and systems that impact quality, the senior executives and managers must be responsible, as elaborated in Figure 2 below.

Total Quality Management is a concept applied in the automobile industry, including the Toyota Corporation. It focuses on continuous improvement across all branches and levels of an organization. Being part of Toyota, the concept defines the way in which the organization can create value for its customers and other stakeholders. Through TQM, Toyota Corporation has been able to create value, which eventually leads to operation efficiencies.

These efficiencies have particularly been achieved by continuous correction of deficiencies identified in the process. A particular interest is the central role that information flow and management have played in enabling TQM initiatives to be implemented, especially through continuous learning and team working culture.

The Toyota way (kaizen), which aims at integrating the workforce suggestions while eliminating overproduction and manufacturing wastes, helps the company to respect all the stakeholders and give clients first priority. The objectives are realized through TPS.

Chary, D. 2009, Production and operations management , Tata McGraw-Hill Education Press, Mumbai.

Huczynski, A. & Buchanan, D. 2007, Organizational behavior; an introductory text, Prentice Hall, New York, NY.

Kanji, G. K. & Asher, M. 1996, 100 methods for total quality management , SAGE Thousands Oak, CA.

Slack, N. et al. 2009, Operations and process management: principles and practice for strategic management, Prentice Hall, New York, NY.

Toyota Motor Corporation 2012, Annual report 2012. Web.

- Google Corporation Investments Evaluation

- How HR Approaches Match Up With the Strategic Initiatives

- Motorola Company's Just-in-Time Implementation

- Toyota Motor Corporation's Sustainability

- Lean Manufacturing: Processes

- Barriers and Facilitators of Workplace Learning

- The Science of Behavior in Business

- Standards, models, and quality: Management

- Managerial and Professional Development: Crowe Horwath CPA limited

- Managerial and Professional Development: Deloitte & Touché Company

- Chicago (A-D)

- Chicago (N-B)

IvyPanda. (2019, June 12). Implementation of Total Quality Management (TQM): Toyota Case Study. https://ivypanda.com/essays/total-quality-management-tqm-implementation-toyota/

"Implementation of Total Quality Management (TQM): Toyota Case Study." IvyPanda , 12 June 2019, ivypanda.com/essays/total-quality-management-tqm-implementation-toyota/.

IvyPanda . (2019) 'Implementation of Total Quality Management (TQM): Toyota Case Study'. 12 June.

IvyPanda . 2019. "Implementation of Total Quality Management (TQM): Toyota Case Study." June 12, 2019. https://ivypanda.com/essays/total-quality-management-tqm-implementation-toyota/.

1. IvyPanda . "Implementation of Total Quality Management (TQM): Toyota Case Study." June 12, 2019. https://ivypanda.com/essays/total-quality-management-tqm-implementation-toyota/.

Bibliography

IvyPanda . "Implementation of Total Quality Management (TQM): Toyota Case Study." June 12, 2019. https://ivypanda.com/essays/total-quality-management-tqm-implementation-toyota/.

Newly Launched - AI Presentation Maker

- Toyota Motor Corporation

- Popular Categories

AI PPT Maker

Powerpoint Templates

Icon Bundle

Kpi Dashboard

Professional

Business Plans

Swot Analysis

Gantt Chart

Business Proposal

Marketing Plan

Project Management

Business Case

Business Model

Cyber Security

Business PPT

Digital Marketing

Digital Transformation

Human Resources

Product Management

Artificial Intelligence

Company Profile

Acknowledgement PPT

PPT Presentation

Reports Brochures

One Page Pitch

Interview PPT

All Categories

Powerpoint Templates and Google slides for Toyota Motor Corporation

Save your time and attract your audience with our fully editable ppt templates and slides..

Item 1 to 60 of 68 total items

- You're currently reading page 1

This report is an extensively researched profile on company Toyota Motor Corporation Company Profile Overview Financials And Statistics From 2014 to 2018 in industry Consumer Goods And FMCG and Retail and Trade and E-Commerce and has been prepared by SlideTeam industry experts after extensively researching through hundreds of data sources. This is part of our Company Profiles products selection, and you will need a Paid account to download the actual report with accurate data and sources for each statistic and fact. Downloaded report will be in Powerpoint and will contain the actual editable slides with the actual data and sources for each data where applicable. Download it immediately and use it for your business.

This slide presents a case study of an automobile company collaborating with an insurance company to enhance insurance services and reduce fraudulent claims. It covers the overview, project name, eligibility criteria, and working framework. Increase audience engagement and knowledge by dispensing information using Case Study 1 Toyota Motor Corporation And Insurance Role Of IoT In Revolutionizing Insurance IoT SS. This template helps you present information on two stages. You can also present information on Project Name, Eligible Vehicle using this PPT design. This layout is completely editable so personaize it now to meet your audiences expectations.

The purpose of this slide is to explore Toyota motor corporations lean manufacturing success. It highlights transformative strategies that optimize efficiency, quality, and competitive advantage. Introducing our Case Study Toyota Motor Corporations Lean Manufacturing Success Ppt Sample set of slides. The topics discussed in these slides are Objective, Strategies, Effect. This is an immediately available PowerPoint presentation that can be conveniently customized. Download it and convince your audience.

The information presented in this slide has been researched by our team of professional business analysts. This is part of our Company Profiles products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will be in Powerpoint and will contain the actual editable slides with the actual data and sources for each data. This slide shows the environmental challenges to overcome by Toyota Motor Corporation in 2050. Download it immediately and use it for your business.

The information presented in this slide has been researched by our team of professional business analysts. This is part of our Company Profiles products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will be in Powerpoint and will contain the actual editable slides with the actual data and sources for each data. This slide shows the History of Toyota Motor Corporation with dates relating to Establishments, Implementations, Joint Venture, Adoption of Kanban Method etc. from 1935 to 2017. Download it immediately and use it for your business.

The information presented in this slide has been researched by our team of professional business analysts. This is part of our Company Profiles products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will be in Powerpoint and will contain the actual editable slides with the actual data and sources for each data. This slide shows the Production Sites including Products, Start of operations and Unit production of Toyota Motor Corporation in Japan as of December 2018. Download it immediately and use it for your business.

The information presented in this slide has been researched by our team of professional business analysts. This is part of our Company Profiles products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will be in Powerpoint and will contain the actual editable slides with the actual data and sources for each data. This slide shows SWOT Strengths, Weakness, Opportunity and Threat of Toyota Motor Corporation in 2018. Download it immediately and use it for your business.

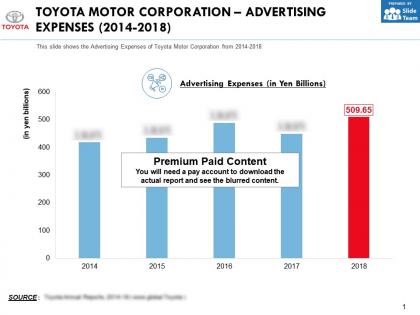

This is a professionally designed visual chart for Toyota Motor Corporation Advertising Expenses 2014 to 2018. This is part of our Data and Statistics products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will contain the editable graph with accurate data, an excel table with the actual data, the exact source of the data and the release date. This slide shows the Advertising Expenses of Toyota Motor Corporation from 2014 to 2018. Download it immediately and use it for your business.

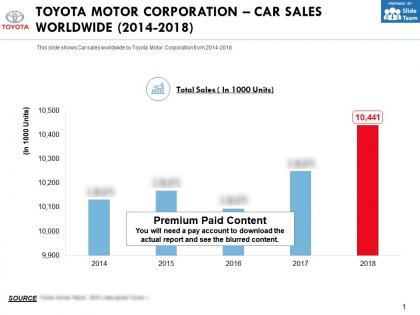

This is a professionally designed visual chart for Toyota Motor Corporation Car Sales Worldwide 2014 to 2018. This is part of our Data and Statistics products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will contain the editable graph with accurate data, an excel table with the actual data, the exact source of the data and the release date. This slide shows Car sales worldwide by Toyota Motor Corporation from 2014 to 2018. Download it immediately and use it for your business.

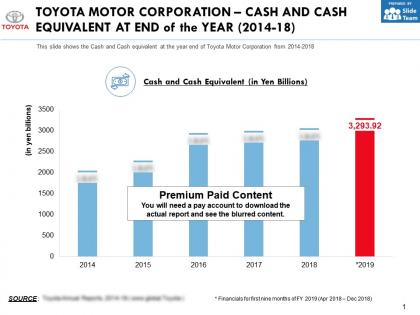

This is a professionally designed visual chart for Toyota Motor Corporation Cash And Cash Equivalent At End Of The Year 2014 to 18. This is part of our Data and Statistics products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will contain the editable graph with accurate data, an excel table with the actual data, the exact source of the data and the release date. This slide shows the Cash and Cash equivalent at the year end of Toyota Motor Corporation from 2014 to 2018. Download it immediately and use it for your business.

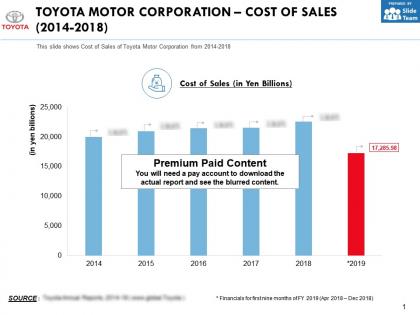

This is a professionally designed visual chart for Toyota Motor Corporation Cost Of Sales 2014 to 2018. This is part of our Data and Statistics products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will contain the editable graph with accurate data, an excel table with the actual data, the exact source of the data and the release date. This slide shows Cost of Sales of Toyota Motor Corporation from 2014 to 2018. Download it immediately and use it for your business.

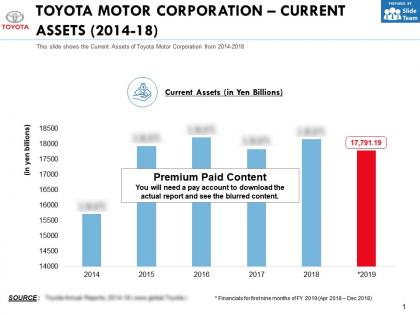

This is a professionally designed visual chart for Toyota Motor Corporation Current Assets 2014 to 18. This is part of our Data and Statistics products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will contain the editable graph with accurate data, an excel table with the actual data, the exact source of the data and the release date. This slide shows the Current Assets of Toyota Motor Corporation from 2014 to 2018. Download it immediately and use it for your business.

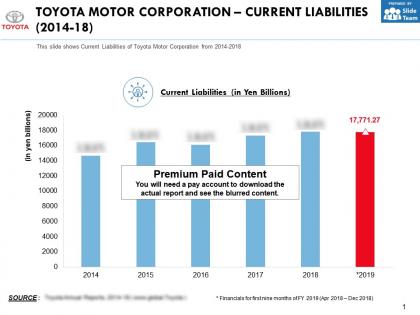

This is a professionally designed visual chart for Toyota Motor Corporation Current Liabilities 2014 to 18. This is part of our Data and Statistics products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will contain the editable graph with accurate data, an excel table with the actual data, the exact source of the data and the release date. This slide shows Current Liabilities of Toyota Motor Corporation from 2014 to 2018 . Download it immediately and use it for your business.

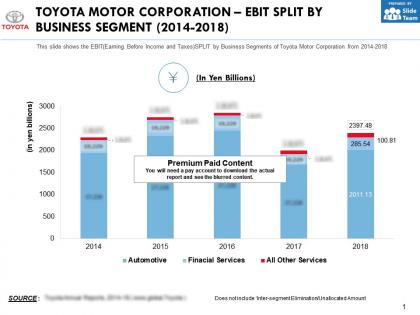

This is a professionally designed visual chart for Toyota Motor Corporation Ebit Split By Business Segment 2014 to 2018. This is part of our Data and Statistics products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will contain the editable graph with accurate data, an excel table with the actual data, the exact source of the data and the release date. This slide shows the EBIT Earning Before Income and Taxes SPLIT by Business Segments of Toyota Motor Corporation from 2014 to 2018. Download it immediately and use it for your business.

This is a professionally designed visual chart for Toyota Motor Corporation Employee Breakup By Regions 2014 to 18. This is part of our Data and Statistics products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will contain the editable graph with accurate data, an excel table with the actual data, the exact source of the data and the release date. This slide shows Toyota Motor Corporation Employee Breakup by Regions from the years 2014 to 2018. Download it immediately and use it for your business.

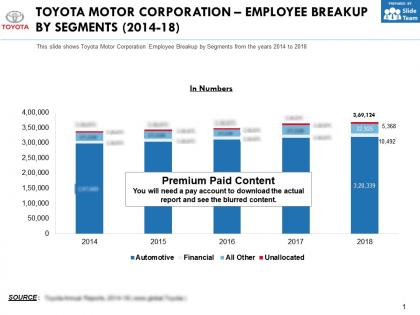

This is a professionally designed visual chart for Toyota Motor Corporation Employee Breakup By Segments 2014 to 18. This is part of our Data and Statistics products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will contain the editable graph with accurate data, an excel table with the actual data, the exact source of the data and the release date. This slide shows Toyota Motor Corporation Employee Breakup by Segments from the years 2014 to 2018. Download it immediately and use it for your business.

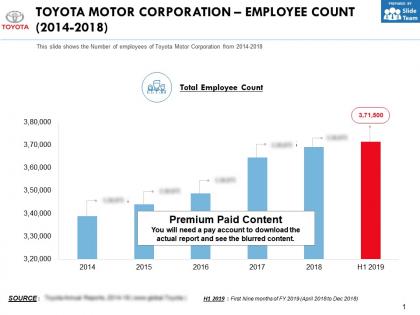

This is a professionally designed visual chart for Toyota Motor Corporation Employee Count 2014 to 2018. This is part of our Data and Statistics products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will contain the editable graph with accurate data, an excel table with the actual data, the exact source of the data and the release date. This slide shows the Number of employees of Toyota Motor Corporation from 2014 to 2018. Download it immediately and use it for your business.

This is a professionally designed visual chart for Toyota Motor Corporation Enterprise Value 2014 to 18. This is part of our Data and Statistics products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will contain the editable graph with accurate data, an excel table with the actual data, the exact source of the data and the release date. This slide shows the enterprise value of Toyota Motor Corporation from the years 2014 to 2018. Download it immediately and use it for your business.

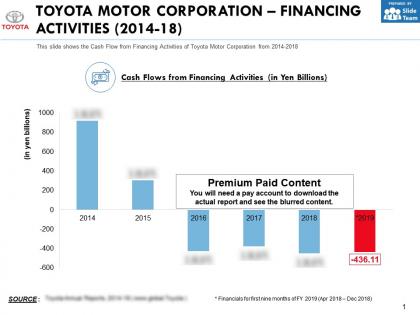

This is a professionally designed visual chart for Toyota Motor Corporation Financing Activities 2014 to 18. This is part of our Data and Statistics products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will contain the editable graph with accurate data, an excel table with the actual data, the exact source of the data and the release date. This slide shows the Cash Flow from Financing Activities of Toyota Motor Corporation from 2014 to 2018. Download it immediately and use it for your business.

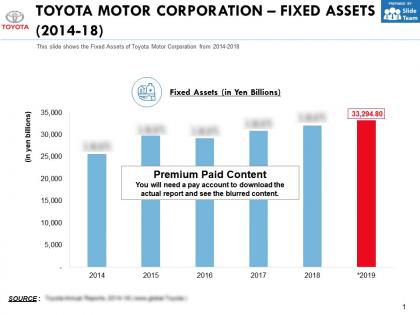

This is a professionally designed visual chart for Toyota Motor Corporation Fixed Assets 2014 to 18. This is part of our Data and Statistics products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will contain the editable graph with accurate data, an excel table with the actual data, the exact source of the data and the release date. This slide shows the Fixed Assets of Toyota Motor Corporation from 2014 to 2018. Download it immediately and use it for your business.

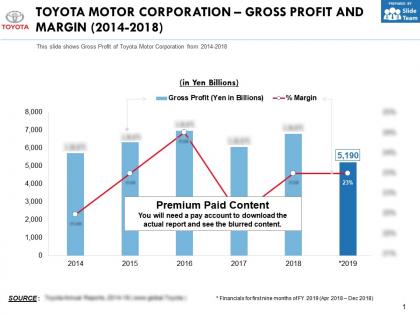

This is a professionally designed visual chart for Toyota Motor Corporation Gross Profit And Margin 2014 to 2018. This is part of our Data and Statistics products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will contain the editable graph with accurate data, an excel table with the actual data, the exact source of the data and the release date. This slide shows Gross Profit of Toyota Motor Corporation from 2014 to 2018. Download it immediately and use it for your business.

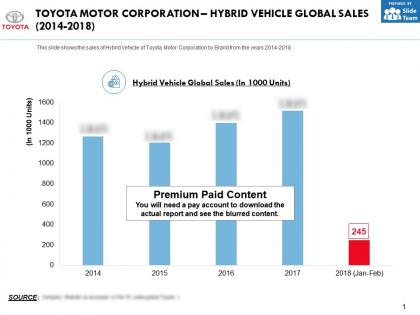

This is a professionally designed visual chart for Toyota Motor Corporation Hybrid Vehicle Global Sales 2014 to 2018. This is part of our Data and Statistics products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will contain the editable graph with accurate data, an excel table with the actual data, the exact source of the data and the release date. This slide shows the sales of Hybrid Vehicle of Toyota Motor Corporation by Brand from the years 2014 to 2018. Download it immediately and use it for your business.

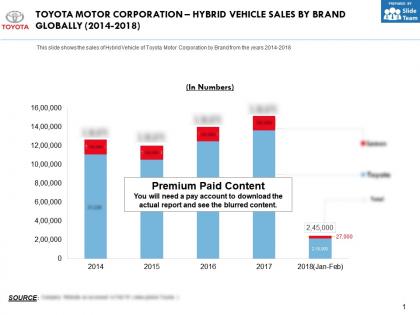

This is a professionally designed visual chart for Toyota Motor Corporation Hybrid Vehicle Sales By Brand Globally 2014 to 2018. This is part of our Data and Statistics products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will contain the editable graph with accurate data, an excel table with the actual data, the exact source of the data and the release date. This slide shows the sales of Hybrid Vehicle of Toyota Motor Corporation by Brand from the years 2014 to 2018. Download it immediately and use it for your business.

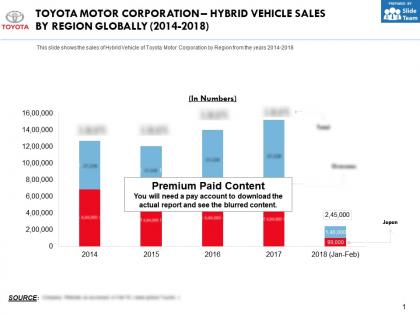

This is a professionally designed visual chart for Toyota Motor Corporation Hybrid Vehicle Sales By Region Globally 2014 to 2018. This is part of our Data and Statistics products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will contain the editable graph with accurate data, an excel table with the actual data, the exact source of the data and the release date. This slide shows the sales of Hybrid Vehicle of Toyota Motor Corporation by Region from the years 2014 to 2018. Download it immediately and use it for your business.

This is a professionally designed visual chart for Toyota Motor Corporation Investing Activities 2014 to 18. This is part of our Data and Statistics products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will contain the editable graph with accurate data, an excel table with the actual data, the exact source of the data and the release date. This slide shows the Cash Flows from Investing activities of Toyota Motor Corporation from 2014 to 2018. Download it immediately and use it for your business.

This is a professionally designed visual chart for Toyota Motor Corporation Investments In PPE 2014 to 18. This is part of our Data and Statistics products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will contain the editable graph with accurate data, an excel table with the actual data, the exact source of the data and the release date. This slide shows the Investments in Property, Plant and Equipment of Toyota Motor Corporation from 2014 to 2018. Download it immediately and use it for your business.

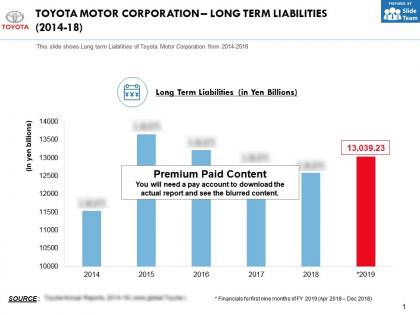

This is a professionally designed visual chart for Toyota Motor Corporation Long Term Liabilities 2014 to 18. This is part of our Data and Statistics products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will contain the editable graph with accurate data, an excel table with the actual data, the exact source of the data and the release date. This slide shows Long term Liabilities of Toyota Motor Corporation from 2014 to 2018. Download it immediately and use it for your business.

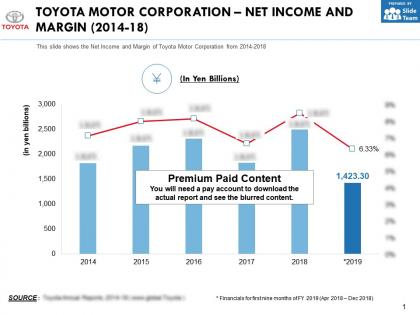

This is a professionally designed visual chart for Toyota Motor Corporation Net Income And Margin 2014 to 18. This is part of our Data and Statistics products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will contain the editable graph with accurate data, an excel table with the actual data, the exact source of the data and the release date. This slide shows the Net Income and Margin of Toyota Motor Corporation from 2014 to 2018. Download it immediately and use it for your business.

This is a professionally designed visual chart for Toyota Motor Corporation Number Of Distributors By Region 2016 to 2018. This is part of our Data and Statistics products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will contain the editable graph with accurate data, an excel table with the actual data, the exact source of the data and the release date. This slide shows Number of Distributors of Toyota Motor Corporation by Regions from 2016 to 18. Download it immediately and use it for your business.

This is a professionally designed visual chart for Toyota Motor Corporation Number Of Plants And Manufacturing Companies By Region 2016 to 2018. This is part of our Data and Statistics products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will contain the editable graph with accurate data, an excel table with the actual data, the exact source of the data and the release date. This slide shows Number of Plants and Manufacturing Companies of Toyota Motor Corporation by Regions from 2016 to 18. Download it immediately and use it for your business.

This is a professionally designed visual chart for Toyota Motor Corporation Number Of Research And Development Sites By Region 2016 to 2018. This is part of our Data and Statistics products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will contain the editable graph with accurate data, an excel table with the actual data, the exact source of the data and the release date. This slide shows Number of Research and Development Sites of Toyota Motor Corporation by Regions from 2016 to 18. Download it immediately and use it for your business.

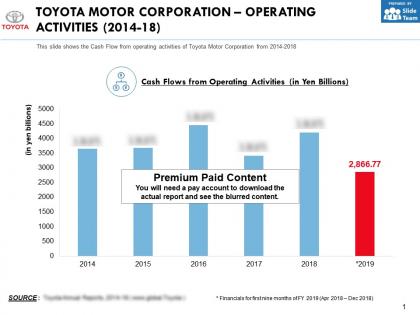

This is a professionally designed visual chart for Toyota Motor Corporation Operating Activities 2014 to 18. This is part of our Data and Statistics products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will contain the editable graph with accurate data, an excel table with the actual data, the exact source of the data and the release date. This slide shows the Cash Flow from operating activities of Toyota Motor Corporation from 2014 to 2018. Download it immediately and use it for your business.

This is a professionally designed visual chart for Toyota Motor Corporation Operating Income And Margin 2014 to 2018. This is part of our Data and Statistics products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will contain the editable graph with accurate data, an excel table with the actual data, the exact source of the data and the release date. This slide shows the Operating Income and Margin of Toyota Motor Corporation from 2014 to 2018. Download it immediately and use it for your business.

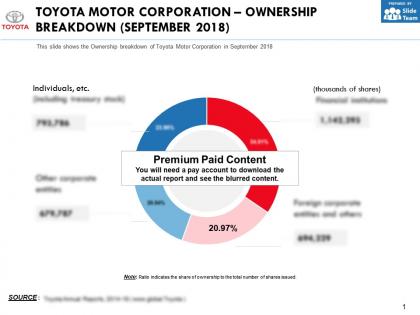

This is a professionally designed visual chart for Toyota Motor Corporation Ownership Breakdown September 2018. This is part of our Data and Statistics products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will contain the editable graph with accurate data, an excel table with the actual data, the exact source of the data and the release date. This slide shows the Ownership breakdown of Toyota Motor Corporation in September 2018. Download it immediately and use it for your business.

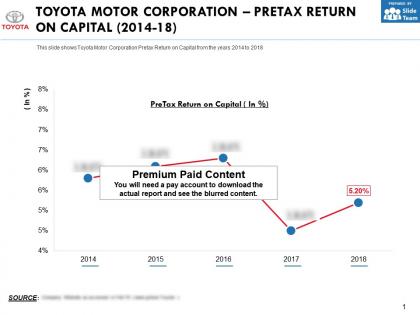

This is a professionally designed visual chart for Toyota Motor Corporation Pretax Return On Capital 2014 to 18. This is part of our Data and Statistics products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will contain the editable graph with accurate data, an excel table with the actual data, the exact source of the data and the release date. This slide shows Toyota Motor Corporation Pretax Return on Capital from the years 2014 to 2018. Download it immediately and use it for your business.

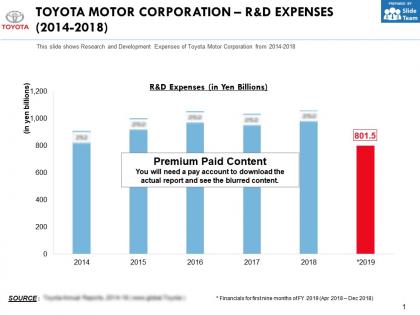

This is a professionally designed visual chart for Toyota Motor Corporation R And D Expenses 2014 to 2018. This is part of our Data and Statistics products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will contain the editable graph with accurate data, an excel table with the actual data, the exact source of the data and the release date. This slide shows Research and Development Expenses of Toyota Motor Corporation from 2014 to 2018. Download it immediately and use it for your business.

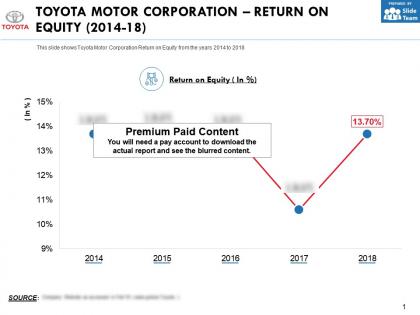

This is a professionally designed visual chart for Toyota Motor Corporation Return On Equity 2014 to 18. This is part of our Data and Statistics products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will contain the editable graph with accurate data, an excel table with the actual data, the exact source of the data and the release date. This slide shows Toyota Motor Corporation Return on Equity from the years 2014 to 2018. Download it immediately and use it for your business.

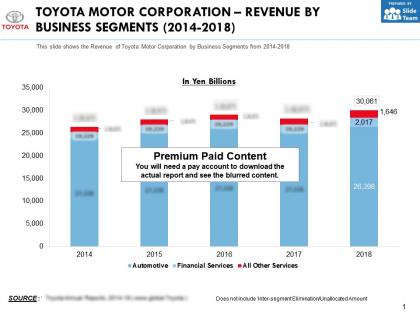

This is a professionally designed visual chart for Toyota Motor Corporation Revenue By Business Segments 2014 to 2018. This is part of our Data and Statistics products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will contain the editable graph with accurate data, an excel table with the actual data, the exact source of the data and the release date. This slide shows the Revenue of Toyota Motor Corporation by Business Segments from 2014 to 2018. Download it immediately and use it for your business.

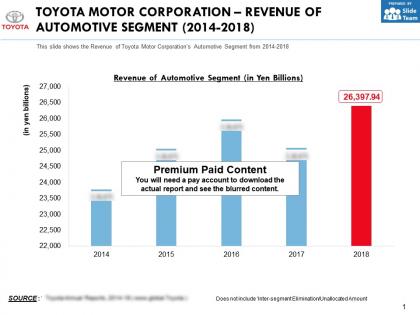

This is a professionally designed visual chart for Toyota Motor Corporation Revenue Of Automotive Segment 2014 to 2018. This is part of our Data and Statistics products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will contain the editable graph with accurate data, an excel table with the actual data, the exact source of the data and the release date. This slide shows the Revenue of Toyota Motor Corporations Automotive Segment from 2014 to 2018. Download it immediately and use it for your business.

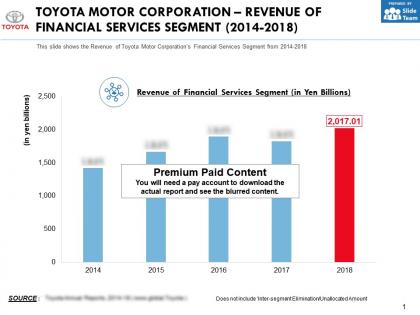

This is a professionally designed visual chart for Toyota Motor Corporation Revenue Of Financial Services Segment 2014 to 2018. This is part of our Data and Statistics products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will contain the editable graph with accurate data, an excel table with the actual data, the exact source of the data and the release date. This slide shows the Revenue of Toyota Motor Corporations Financial Services Segment from 2014 to 2018. Download it immediately and use it for your business.

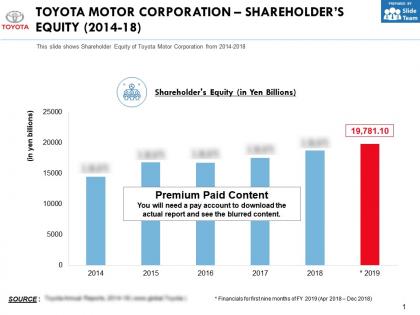

This is a professionally designed visual chart for Toyota Motor Corporation Shareholders Equity 2014 to 18. This is part of our Data and Statistics products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will contain the editable graph with accurate data, an excel table with the actual data, the exact source of the data and the release date. This slide shows Shareholder Equity of Toyota Motor Corporation from 2014 to 2018. Download it immediately and use it for your business.

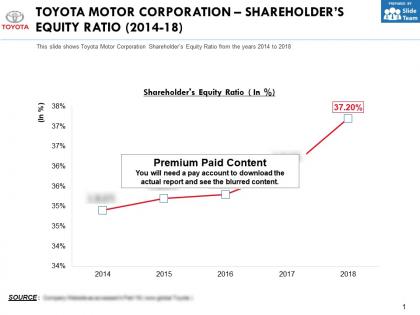

This is a professionally designed visual chart for Toyota Motor Corporation Shareholders Equity Ratio 2014 to 18. This is part of our Data and Statistics products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will contain the editable graph with accurate data, an excel table with the actual data, the exact source of the data and the release date. This slide shows Toyota Motor Corporation Shareholders Equity Ratio from the years 2014 to 2018. Download it immediately and use it for your business.

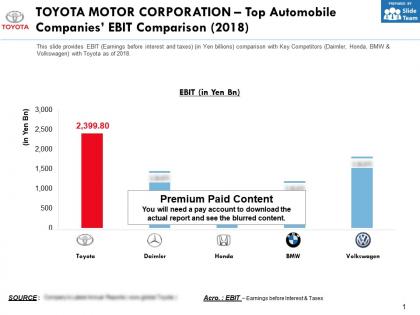

This is a professionally designed visual chart for Toyota Motor Corporation Top Automobile Companies Ebit Comparison 2018. This is part of our Data and Statistics products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will contain the editable graph with accurate data, an excel table with the actual data, the exact source of the data and the release date. This slide provides EBIT Earnings before interest and taxes in Yen billions comparison with Key Competitors Daimler, Honda, BMW and Volkswagen with Toyota as of 2018. Download it immediately and use it for your business.

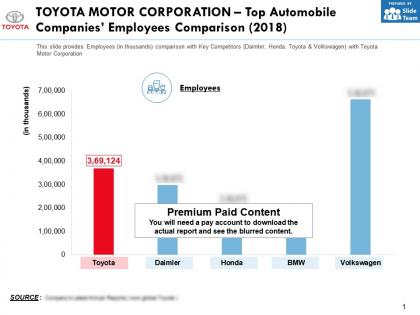

This is a professionally designed visual chart for Toyota Motor Corporation Top Automobile Companies Employees Comparison 2018. This is part of our Data and Statistics products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will contain the editable graph with accurate data, an excel table with the actual data, the exact source of the data and the release date. This slide provides Employees in thousands comparison with Key Competitors Daimler, Honda, Toyota and Volkswagen with Toyota Motor Corporation. Download it immediately and use it for your business.

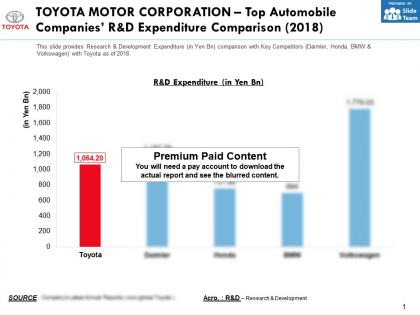

This is a professionally designed visual chart for Toyota Motor Corporation Top Automobile Companies R And D Expenditure Comparison 2018. This is part of our Data and Statistics products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will contain the editable graph with accurate data, an excel table with the actual data, the exact source of the data and the release date. This slide provides Research and Development Expenditure in Yen Bn comparison with Key Competitors Daimler, Honda, BMW and Volkswagen with Toyota as of 2018. Download it immediately and use it for your business.

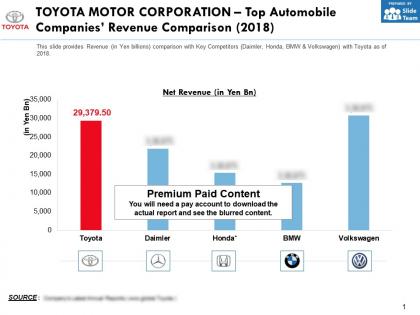

This is a professionally designed visual chart for Toyota Motor Corporation Top Automobile Companies Revenue Comparison 2018. This is part of our Data and Statistics products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will contain the editable graph with accurate data, an excel table with the actual data, the exact source of the data and the release date. This slide provides Revenue in Yen billions comparison with Key Competitors Daimler, Honda, BMW and Volkswagen with Toyota as of 2018. Download it immediately and use it for your business.

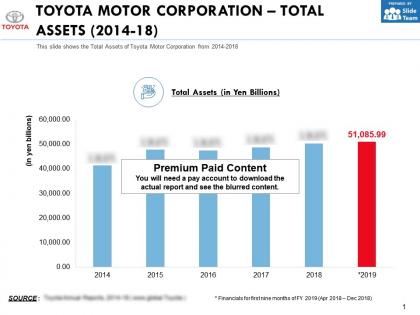

This is a professionally designed visual chart forToyota Motor Corporation Total Assets 2014 to 18. This is part of our Data and Statistics products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will contain the editable graph with accurate data, an excel table with the actual data, the exact source of the data and the release date. This slide shows the Total Assets of Toyota Motor Corporation from 2014 to 2018. Download it immediately and use it for your business.

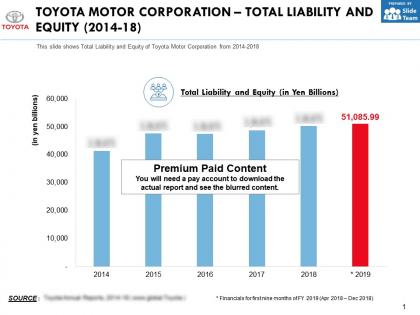

This is a professionally designed visual chart for Toyota Motor Corporation Total Liability And Equity 2014 to 18. This is part of our Data and Statistics products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will contain the editable graph with accurate data, an excel table with the actual data, the exact source of the data and the release date. This slide shows Total Liability and Equity of Toyota Motor Corporation from 2014 to 2018. Download it immediately and use it for your business.

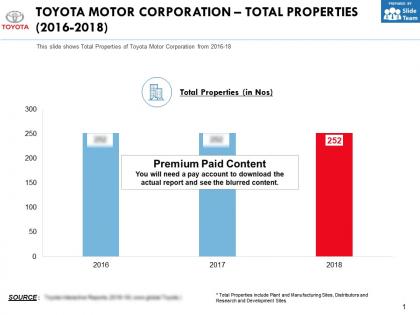

This is a professionally designed visual chart for Toyota Motor Corporation Total Properties 2016 to 2018. This is part of our Data and Statistics products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will contain the editable graph with accurate data, an excel table with the actual data, the exact source of the data and the release date. This slide shows Total Properties of Toyota Motor Corporation from 2016 to 18. Download it immediately and use it for your business.

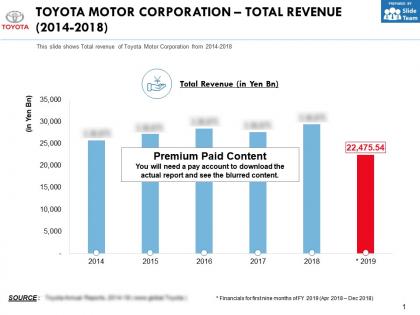

This is a professionally designed visual chart for Toyota Motor Corporation Total Revenue 2014 to 2018. This is part of our Data and Statistics products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will contain the editable graph with accurate data, an excel table with the actual data, the exact source of the data and the release date. This slide shows Total revenue of Toyota Motor Corporation from 2014 to 2018. Download it immediately and use it for your business.

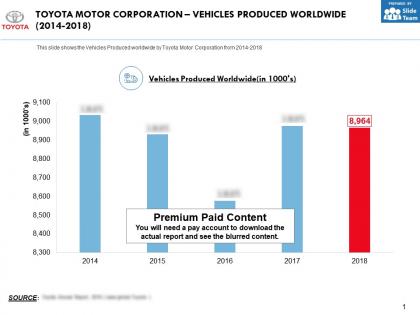

This is a professionally designed visual chart for Toyota Motor Corporation Vehicles Produced Worldwide 2014 to 2018. This is part of our Data and Statistics products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will contain the editable graph with accurate data, an excel table with the actual data, the exact source of the data and the release date. This slide shows the Vehicles Produced worldwide by Toyota Motor Corporation from 2014 to 2018. Download it immediately and use it for your business.

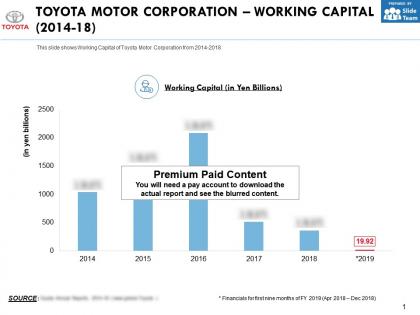

This is a professionally designed visual chart for Toyota Motor Corporation Working Capital 2014 to 18. This is part of our Data and Statistics products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will contain the editable graph with accurate data, an excel table with the actual data, the exact source of the data and the release date. This slide shows Working Capital of Toyota Motor Corporation from 2014 to 2018. Download it immediately and use it for your business.

This is a professionally designed visual chart for Toyota Motor Corporation Customer Satisfaction In U.S 2014 to 18. This is part of our Data and Statistics products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will contain the editable graph with accurate data, an excel table with the actual data, the exact source of the data and the release date. This slide shows Customer satisfaction Index score of Toyota Motor Corporation from 2014 to 2018. Download it immediately and use it for your business.

The information presented in this slide has been researched by our team of professional business analysts. This is part of our Company Profiles products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will be in Powerpoint and will contain the actual editable slides with the actual data and sources for each data. This slide shows the Global Vision of Toyota Motor Corporation for the year 2018. Download it immediately and use it for your business.

The information presented in this slide has been researched by our team of professional business analysts. This is part of our Company Profiles products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will be in Powerpoint and will contain the actual editable slides with the actual data and sources for each data. This slide shows the Introduction of Toyota Motor Corporation stating its Director, Capital, Head Office, Employees, Business Segments etc. for 2018. Download it immediately and use it for your business.

The information presented in this slide has been researched by our team of professional business analysts. This is part of our Company Profiles products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will be in Powerpoint and will contain the actual editable slides with the actual data and sources for each data. This slide shows the investments of Toyota Motor Corporation in Fuels and Powertrain as of March 2018. Download it immediately and use it for your business.

The information presented in this slide has been researched by our team of professional business analysts. This is part of our Company Profiles products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will be in Powerpoint and will contain the actual editable slides with the actual data and sources for each data. This slide shows the brief introduction about Toyota Motor Corporation such as founder, employees, revenue, market cap etc. for 2018. Download it immediately and use it for your business.

The information presented in this slide has been researched by our team of professional business analysts. This is part of our Company Profiles products selection, and you will need a Paid account to download the actual report with accurate data and sources. Downloaded report will be in Powerpoint and will contain the actual editable slides with the actual data and sources for each data. This slide shows the Major Brands HINO, RANZ, LEXUS etc. of Toyota Motor Corporation for 2018. Download it immediately and use it for your business.

- SUGGESTED TOPICS

- The Magazine

- Newsletters

- Managing Yourself

- Managing Teams

- Work-life Balance

- The Big Idea

- Data & Visuals

- Reading Lists